Gear Designer

Software

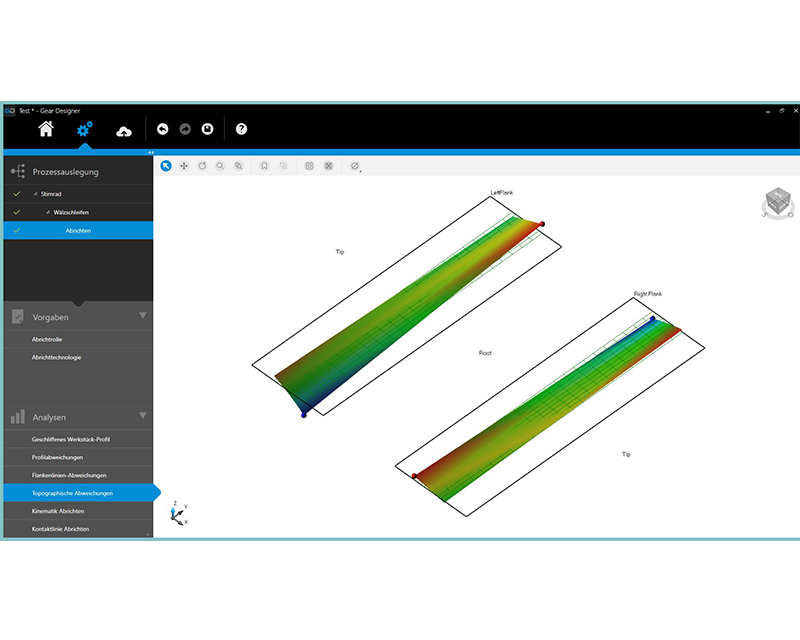

Process design and analysis for continuous generating grinding

In cylindrical gears, the gear flank form is designed based on functional requirements without taking a potential manufacturing process into account. But can the desired modifications actually be manufactured? In Gear Designer, the manufacturable geometry is determined through simulation of the dressing and grinding process. Integrated optimization algorithms adapt the manufacturable geometry to fit the specification – the function-oriented geometry – through targeted modification of the dressing and grinding process kinematics.