Industrial Gear Units

Industry Solutions

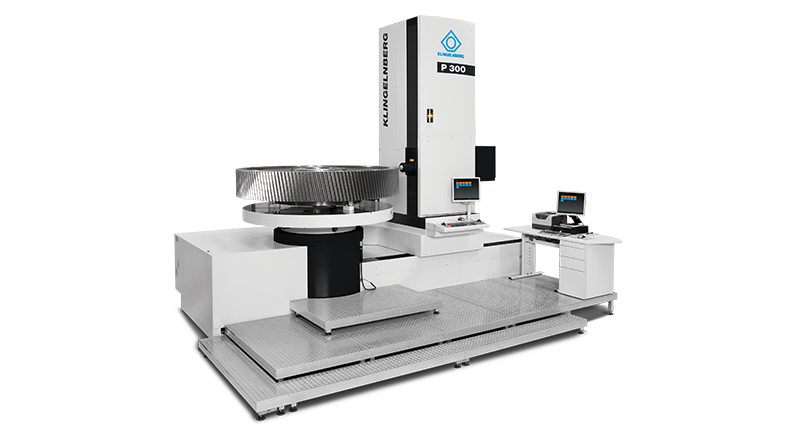

From grain mills to tunnel boring machines and 800-ton excavators: The industrial gear unit sector consists of many different applications, all of which make considerable demands of the reliability of the drive components. Industrial gear units are designed to achieve big things – but should be as compact as possible despite their efficiency. Whereas their output is increasing all the time, the transmission units themselves are becoming smaller and lighter.

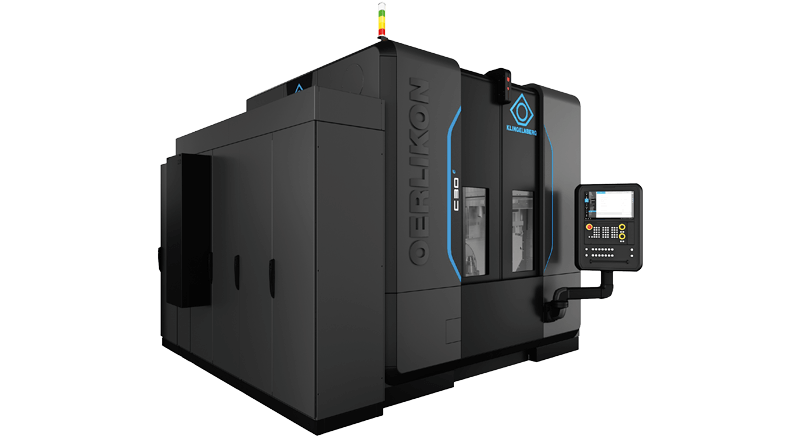

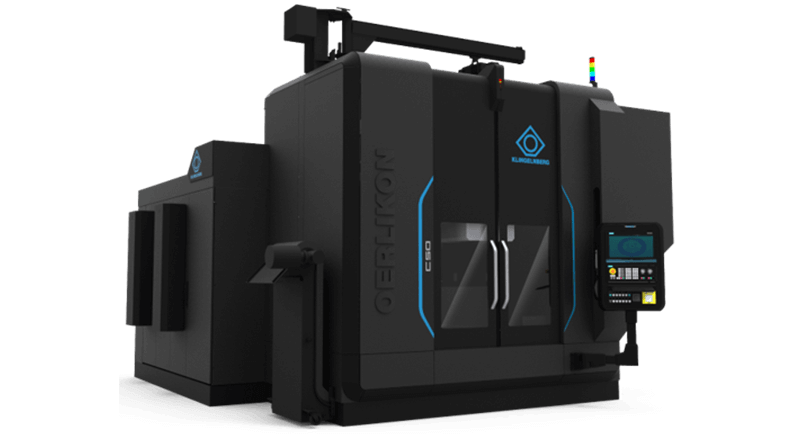

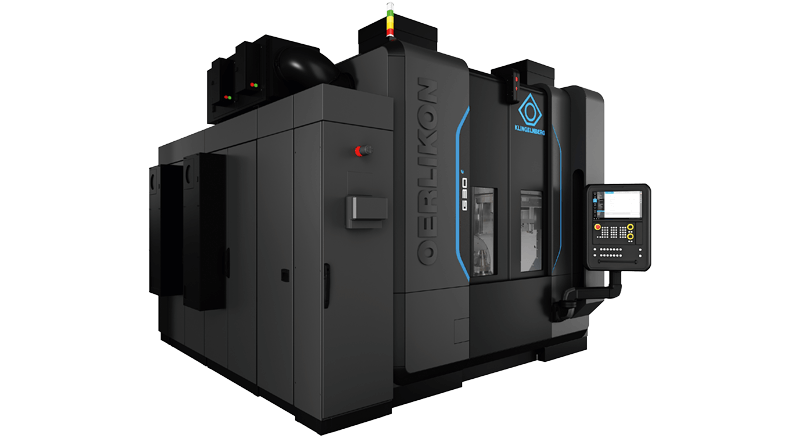

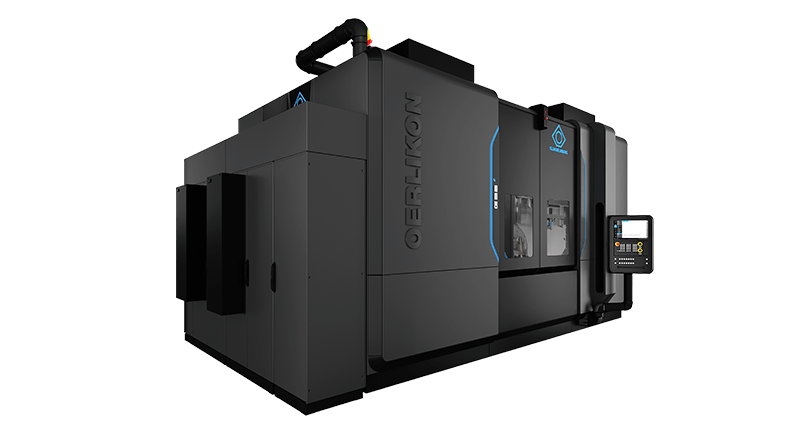

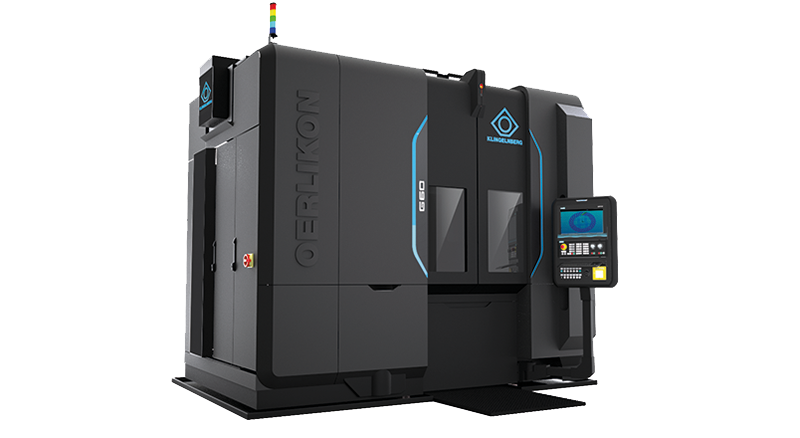

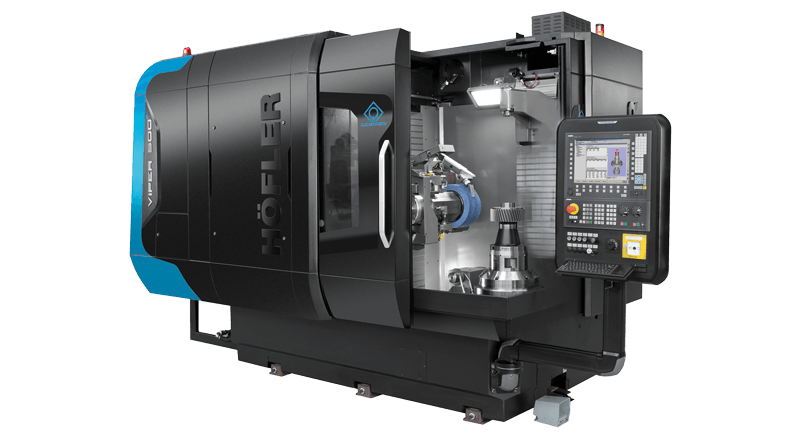

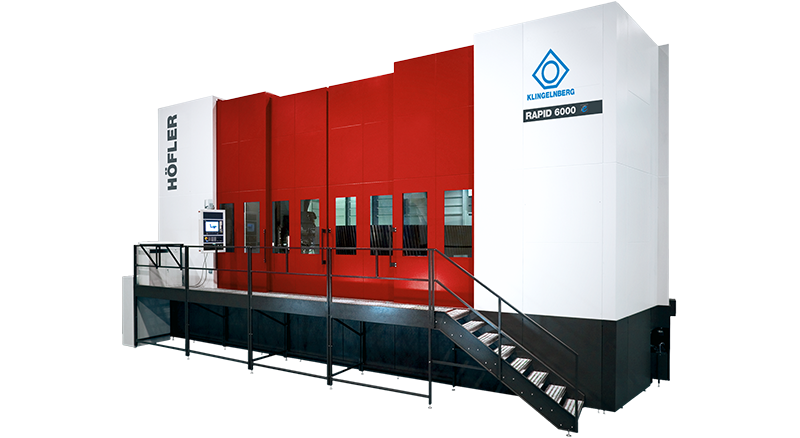

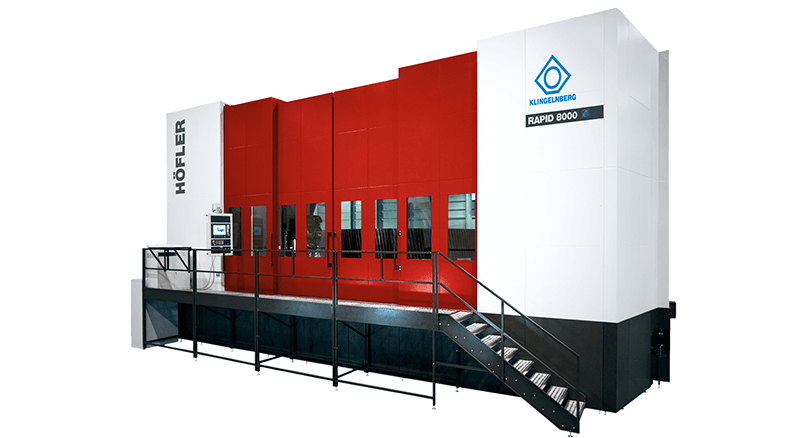

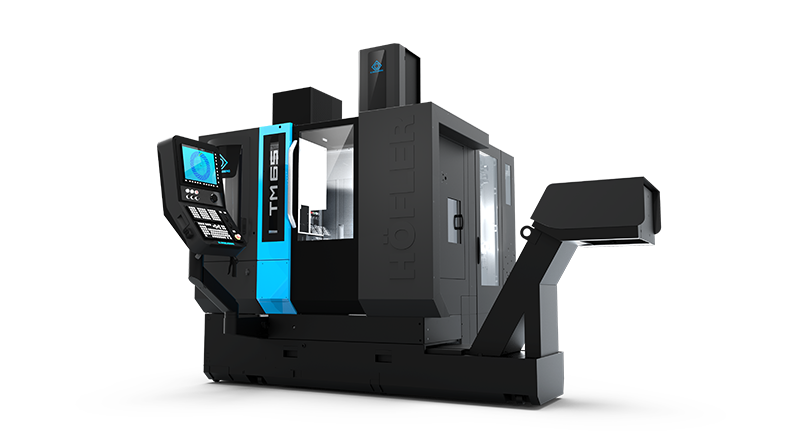

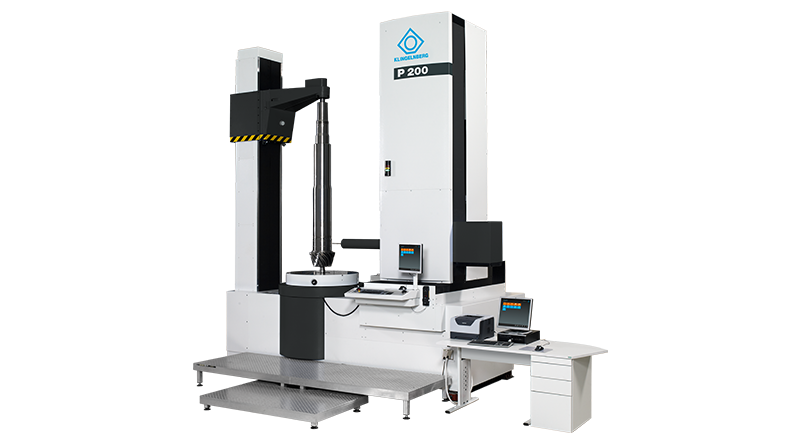

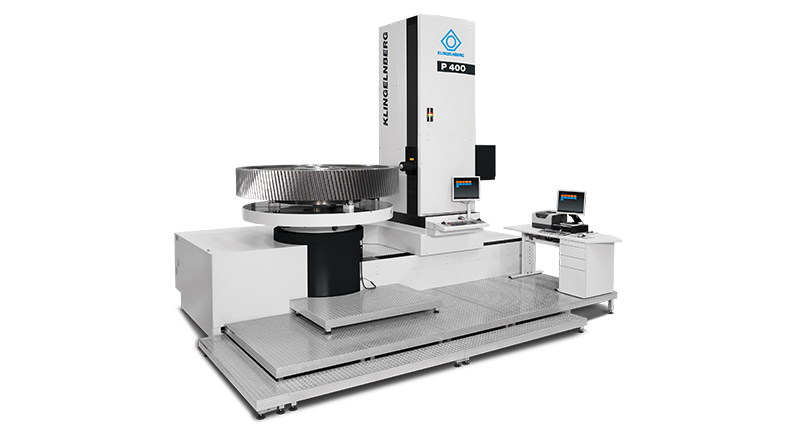

This high power density is a real challenge for the antifriction bearings that are used in the units: They must be reliable and durable, compact, and capable of supporting high loads. Low friction coefficients and quiet running are additional requirements that must be met. The production process must be both individual and flexible: Bevel gears and cylindrical gears for these areas are often produced by companies specializing in small lot sizes and a wide variety of products. A rigid machine structure and flexible, cost-effective tool systems – the like of which are only provided by Klingelnberg – are the keys to success for being among the market leaders.