Wind Power

Industry Solutions

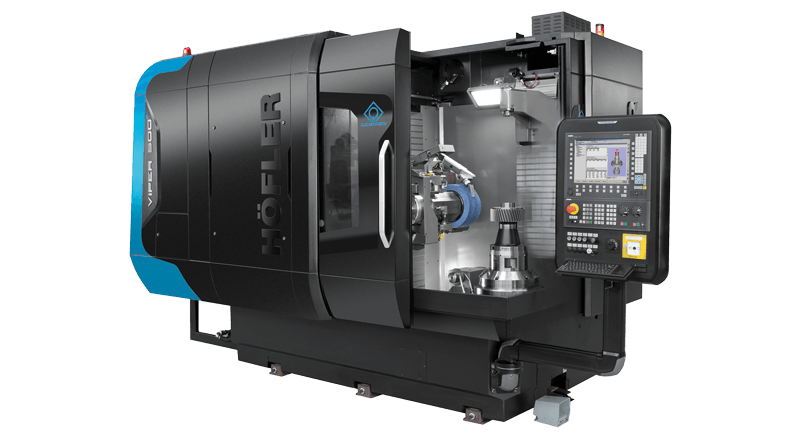

Wind power plants contain a wide variety of toothed gear drives for different tasks: semi-rotary drives for adjusting the machine housing, drives for adjusting the rotor blades, and gearboxes for adapting the rotor speed to the generator speed. To manufacture this variety of toothed gears with maximum productivity, the market requires machines that can get the most out of the potential that modern carbide tools offer.

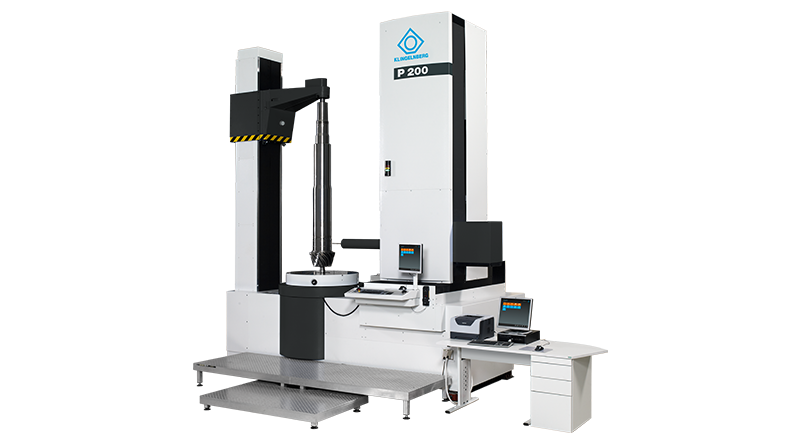

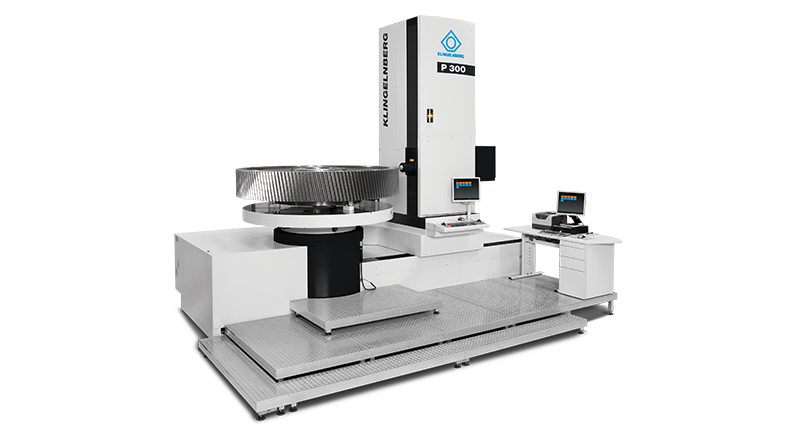

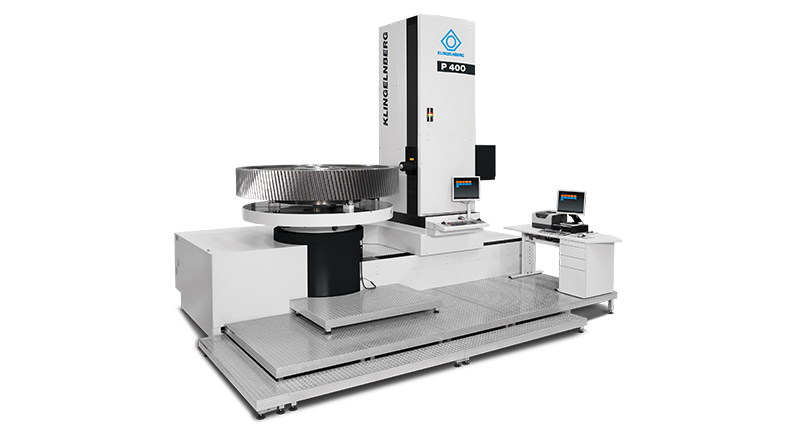

Only optimally cut cylindrical gears are used in wind power. This is because only perfect gear geometry provides optimal transmission of force for highly efficient wind power plants while ensuring extremely quiet running behavior. High-precision gearing quality increases the service life of individual gearbox components, which significantly reduces maintenance costs. Precision measuring centers from Klingelnberg ensure that the optimal gear geometry is maintained with a high degree of accuracy, and that appropriate quality certification is provided.