OERLIKON Bevel Gear Technology

Business Divisions

Intelligent solutions for discerning users

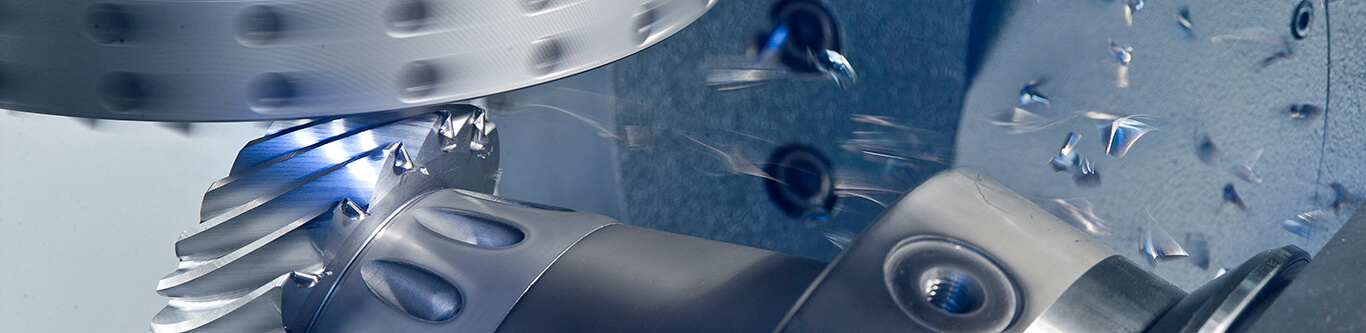

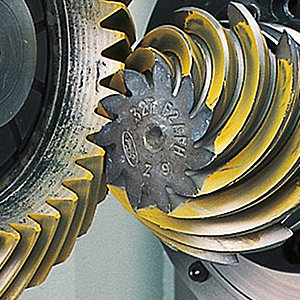

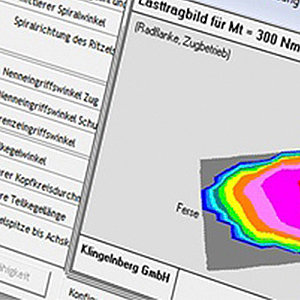

The Oerlikon Bevel Gear Technology division does not just allow users to manufacture bevel gears economically and with high precision. All machines in the system have been designed to work together to enable pre-machining and finishing of even the most complex gears. Klingelnberg offers the most advanced technology and the most efficient machines for each and every step in the process chain. The production process chain for bevel gears includes tool preparation, cutting, measuring, hardening, grinding or lapping and testing, among others. The powerful KIMoS (Klingelnberg integrated Manufacturing of Spiral Bevel Gears) design software and the Closed Loop concept ensure transparency and documented quality throughout the entire process chain. Oerlikon bevel gear machines are developed with real-world applications in mind and meet the varying demands of a whole range of industries. The target markets include the automotive industry, the commercial vehicle industry, the agricultural industry, shipbuilding and aviation, as well as industrial gearbox manufacturing and plant engineering. As a leading system supplier and in combination with these high-performance tool systems, Klingelnberg meets every requirement for flexible, efficient production — for the smallest and the largest batch sizes.