Rolling Bearings Analysis

Applications

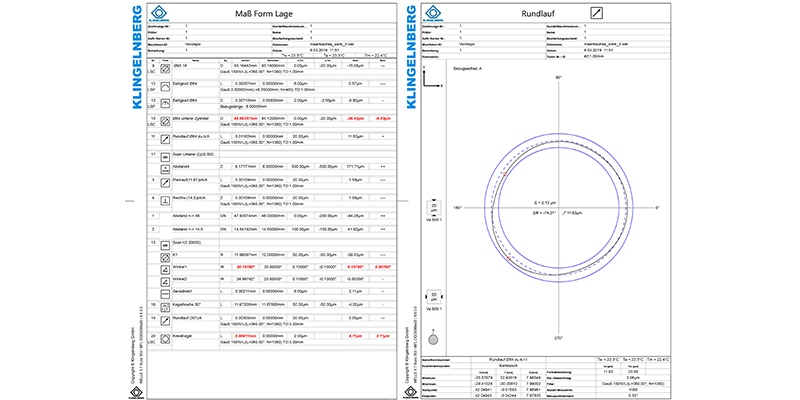

Smart Roller Bearings Analysis – “DONE-IN-ONE”

All Klingelnberg Precision Measuring Centers have the capability to accurately analyze and measure roller bearings and roller bearing elements to an extremely high degree of precision. Based on the manufacturer data and specifications, measuring runs and clear, conclusive protocols are created automatically in compliance with current standards and regulations. The series variations and quality grades of the bearings are supported by the innovative Klingelnberg software. Additional measurement tasks based on specific requirements of the bearing manufacturer are also easily implemented. The specifications of these highly accurate precision measuring centers make them ideal for in-process inspection of rolling bearings and rolling bearing elements in the immediate production environment. Thanks to standard interfaces, the results feed directly into the process and ensure appropriate responses and actions in the upstream and downstream processes.