High-Performance Tools HYCON

Series Tools

The Klingelnberg HYPOFLEX® method for straight bevel gears

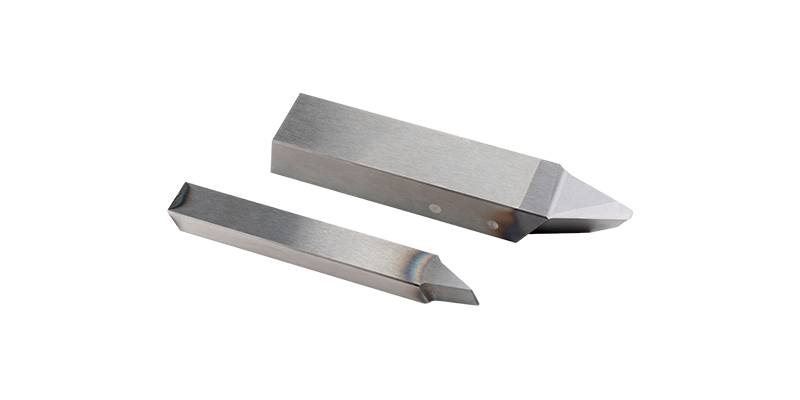

The HYPOFLEX® method is a well-established method for series production of straight bevel gears on all Klingelnberg cutting machines. The continuous indexing method integrates seamlessly into the existing Closed Loop bevel gear production. High-quality, eco-friendly dry processing takes place with a highly productive tool system consisting of a single-part cutter head in the HYCON or ARCON® series and fully coated (3FS) carbide stick blades.