Series Tools

Tools & Fixtures

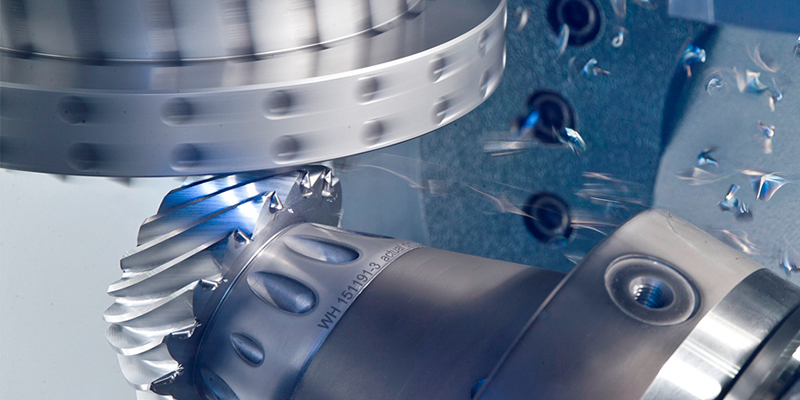

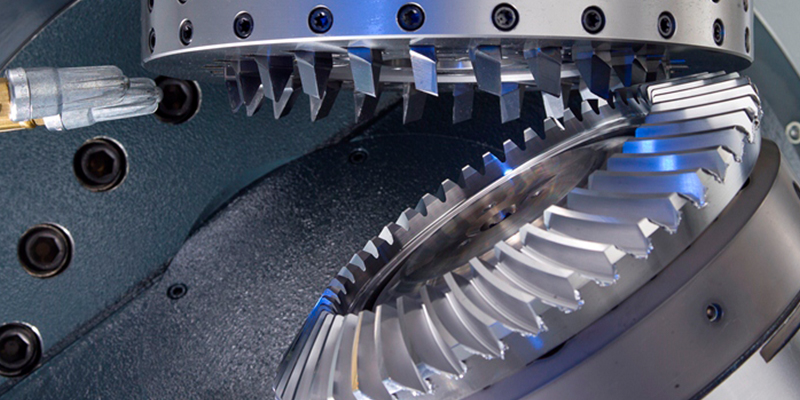

KLINGELNBERG series tools – safeguarding smooth processes

Large-scale production (in the automotive industry, for example) not only places high expectations on product accuracy but also demands maximum productivity with minimal costs. The requirements with respect to tool accuracy, service life, adjustability of the tools and regrinding capability of the blades are fulfilled by the ARCON® and SPIRON®cutter head system. Large numbers of blade groups, very good static and dynamic strength properties and carbide stick blades (coated if necessary) ensure high product quality and productivity along with optimized tool costs.

- Outstanding setting accuracy of the cutting edge position

- Secure stick blade fixing using two pressing screws

- Automated, vertical positioning capability thanks to spring-loaded screw