High-performance Tools ARCON®

Series Tools

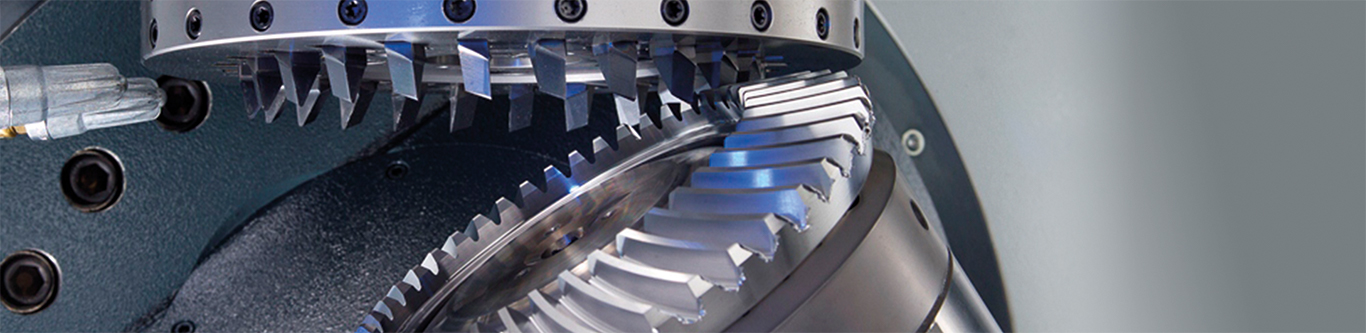

The Klingelnberg single-indexing ARCON® method (Face Milling)

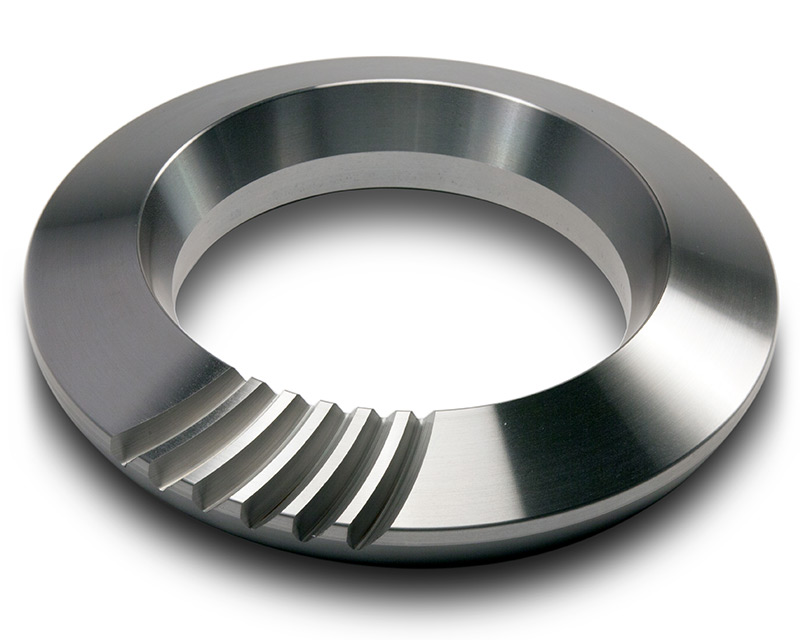

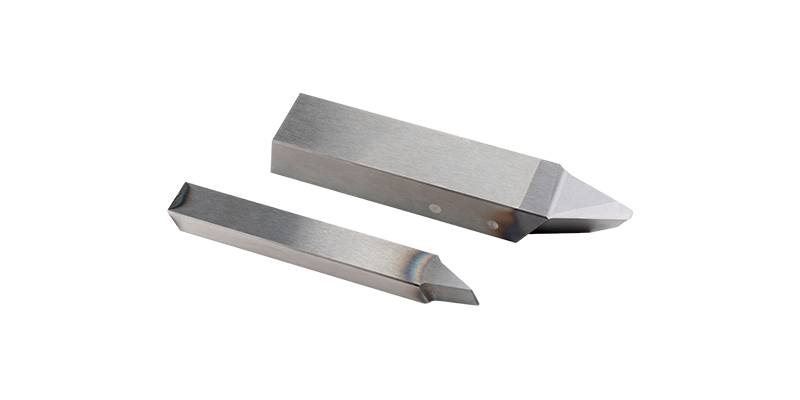

The ARCON® method is a well-established method worldwide for highly productive large-scale production of spiral and hypoid bevel gears. It provides exceptional performance, in particular with the patented solid profile TWIN BLADE by Klingelnberg tool geometry which operates with a maximum number of blades. The method meets the highest quality standards in combination with an environmentally friendly dry production process, based on a tool system consisting of a single-part cutter head and fully coated carbide stick blades.