PULSAR

Software

Industry 4.0 – for secondary processes, too

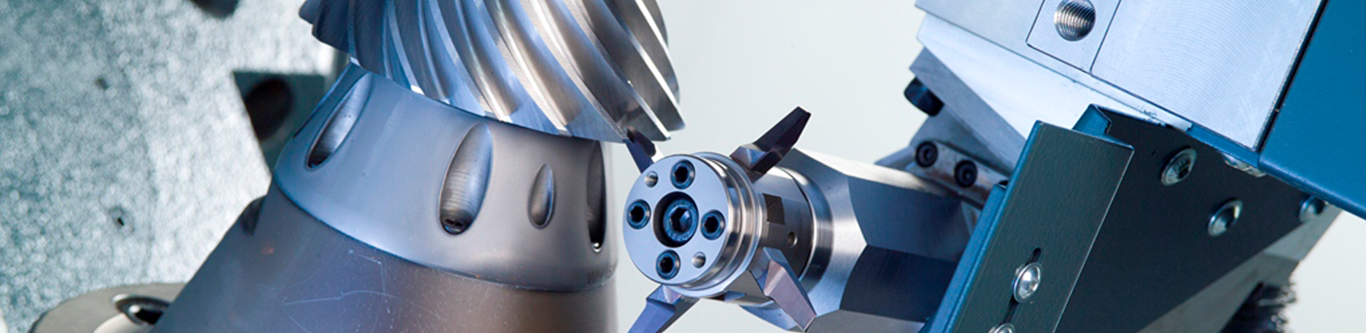

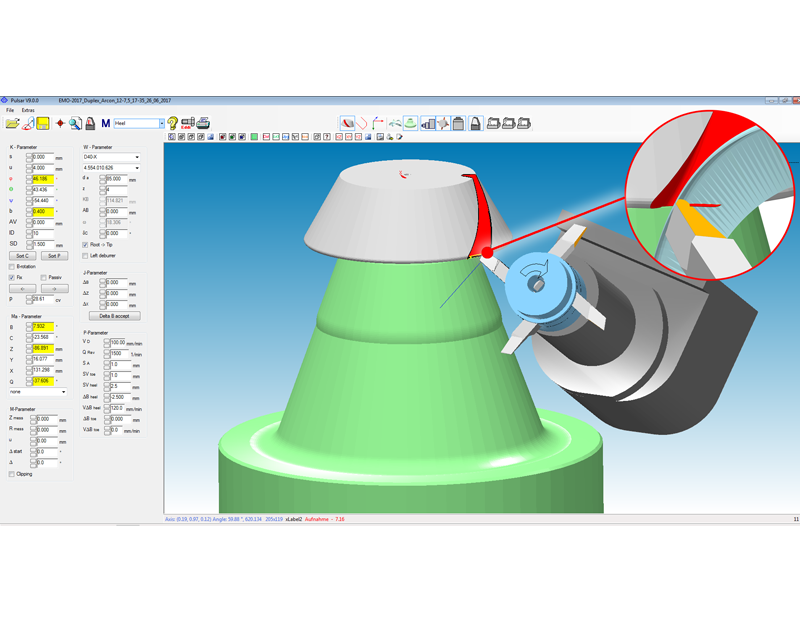

Process and tool design for deburring

Pulsar is used to configure the geometry of deburring cutters for Oerlikon bevel gear cutting machines equipped with a deburring unit, including the kinematics used for deburring. Depending on the selected machine type, different systems (tool, kinematics) are taken into account. Deburring configurations for MultiCut processes can be developed, simulated and tested for collision using Pulsar. The data defined during the simulation are stored in the neutral data in the database and are thus available directly for use in tool preparation and production.