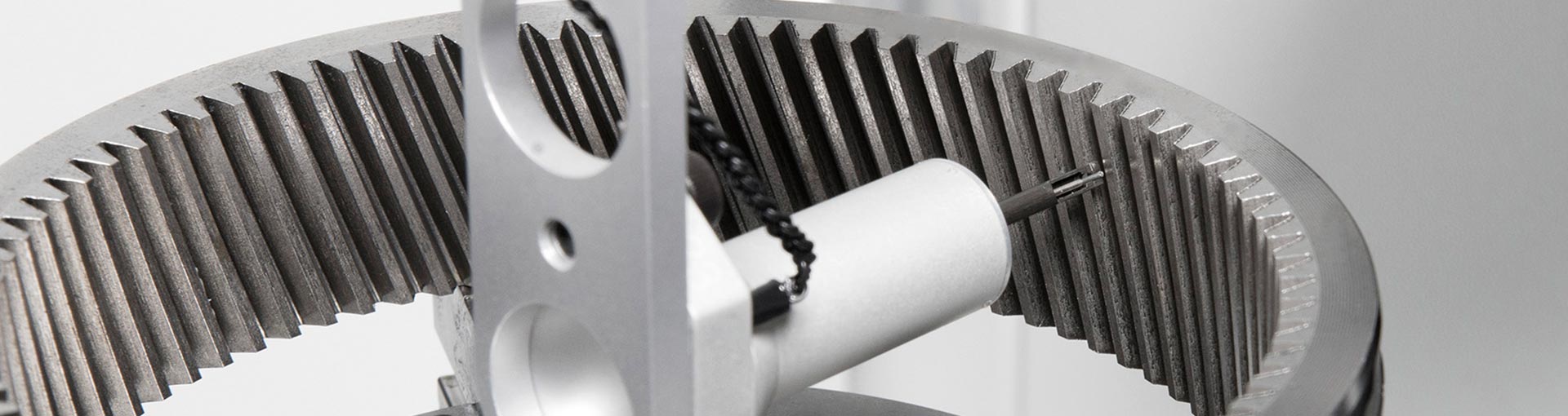

ROUGHNESS MEASUREMENT OF INTERNAL GEARINGS

Product Highlights

- Fully automatic roughness measurement now also possible for internal gearings

- Starting from module 0.9 mm

- High-precision sensing and evaluation of superfine structures on vibration-ground gearings

With Klingelnberg’s tried-and-tested roughness measurement technology, it is now possible to measure roughness on the tooth flank surface of internal gearings as well. All evaluation options familiar from roughness measurement of external cylindrical gears and bevel gears are available. The established integration into an automated process with fully automatic measuring probe change is also available for internal gearings. Gearing and roughness measurement can therefore take place in a single clamping for internal gearings as well.

- Evaluation of roughness parameters in accordance with DIN EN ISO 4287 (Ra, Rz, Rt, Rmax)

- Evaluation of contact ratio parameters in accordance with DIN EN ISO 13565-2 (Rk, Rpk, Rvk, MR1, MR2)

- Skid sensing system for effective separation of the usable signal from ambient influences

- Integrated motorized swivel device for automatic alignment of the diamond needle with a diamond tip radius of 2 µm

- Comprehensive collision protection

- Optimized design to protect the diamond needle

- Extremely high resolution of 7 nm

- Robust, reproducible measuring results, even on extremely smooth surfaces

- Easy handling through integration into the normal measuring process

- Precise measurement, even in the shop-floor environment

- Fully automatic procedure for measuring probe change (option)