Bevel Gear Software

Software

FROM DRAFT TO OPTIMUM

For every step in bevel gear production, systems supplier Klingelnberg offers a full range of IT concepts and software solutions:

KIMOS: THE DEVELOPMENT AND DESIGN SOFTWARE

Featuring convenient data creation and management options, the Klingelnberg Integrated Manufacturing of Spiral Bevel Gears (KIMoS) program package supports every step in the development and design of bevel gear technology, ensuring that the end result precisely matches what was previously designed on the computer. KIMoS forms the basis for the Klingelnberg network. A multiple-machine-capable Windows NT network optimally links development and production and allows for an ultra-efficient production management process. All Klingelnberg machines – from the blade grinding machine to the precision measuring center – have a neutral data interface to connect to this network.

METEORIT: THE TEST SOFTWARE FOR BLADES

Meteorit is the software solution for measuring all KIMoS-calculated blades with a rectangular cross-section. Nearly all blade systems are supported. Meteorit is the basis for calculating machine corrections for Oerlikon B 10, B 24, and B 27 blade grinding machines.

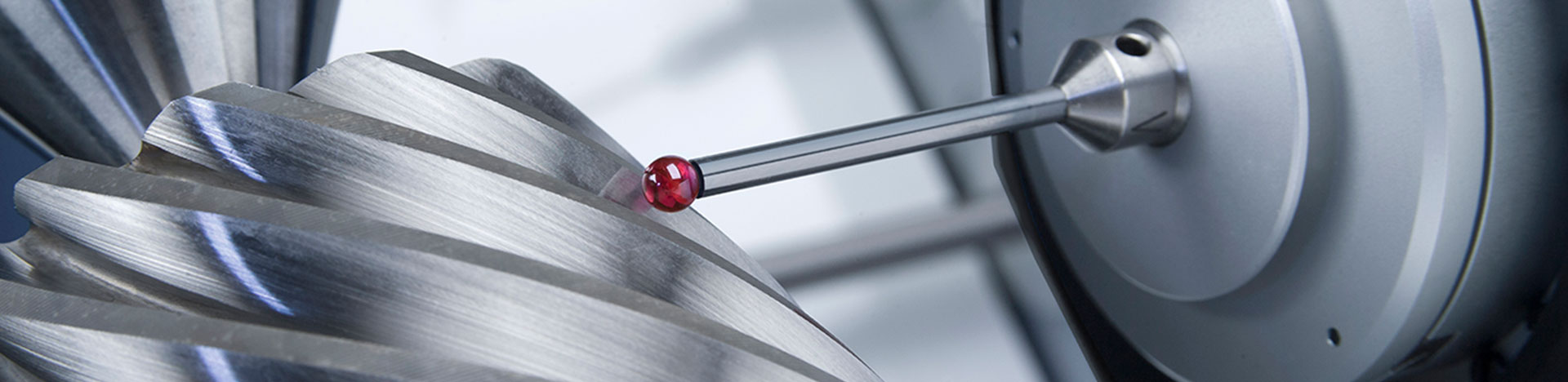

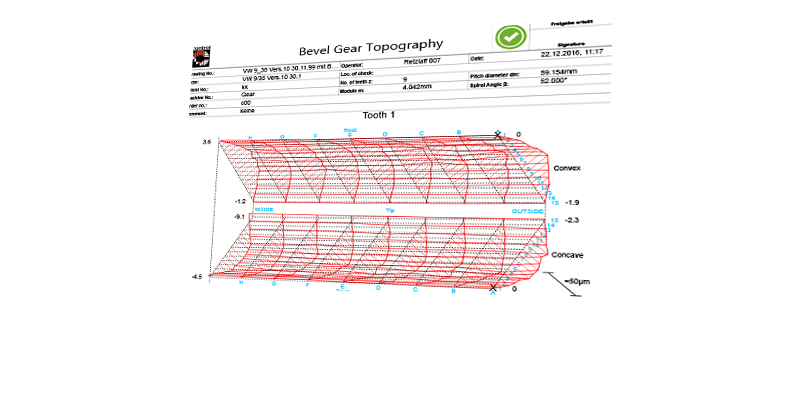

PRECISION MEASURING CENTERS: TESTING OF SPIRAL BEVEL GEARS

Spiral bevel gear testing on precision measuring centers guarantees highly precise, rapid production monitoring and control. Here flank topography based on calculated nominal data is recorded and evaluated with a selectable measurement grid, allowing all production-relevant parameters to be identified. In addition, pitch is measured, tooth height and depth are ascertained, and root radiusing is determined. The pitch results can be evaluated according to numerous international and national standards, such as DIN.

KOMET5: THE CORRECTION PROGRAM

KOMET5, Klingelnberg’s production control program, is designed to correct machine settings and/or tool data during production of bevel gear tooth systems and Hirth joints. Klingelnberg is the only supplier on the market to have implemented an innovative closed-loop assistance system, based on the intuitive KOMET5 program. Once program- and data-specific parameters have been configured, KOMET5 is a fully automatic correction program enabling a closed loop between bevel gear cutting and grinding machines and precision measuring centers. Machine setting values are independently adjusted to the nominal data with such precision that deviations measure a mere two to three micrometers – a quantum leap in both quality and increased productivity.