KIMoS

Software

Industry 4.0 in practice: Design of bevel gear geometry and the manufacturing process

Geometry, process, and tool design for bevel gears

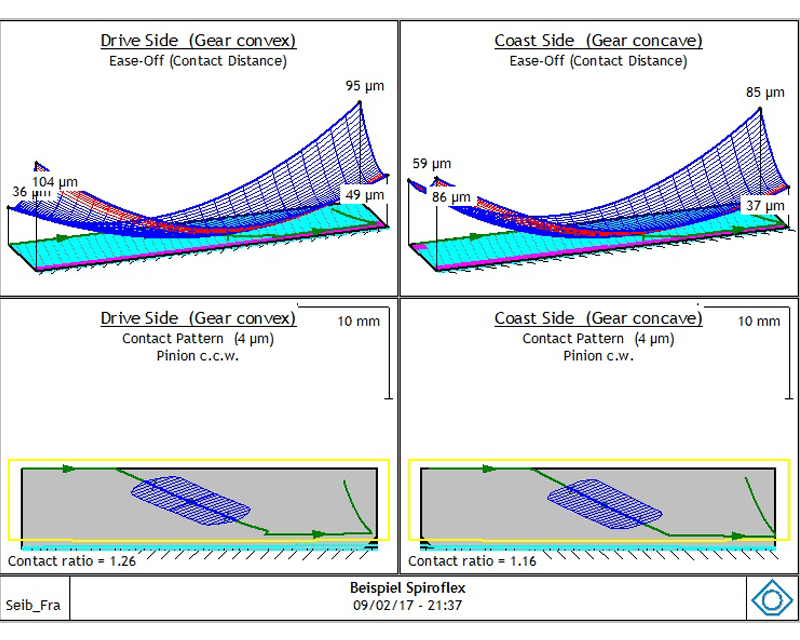

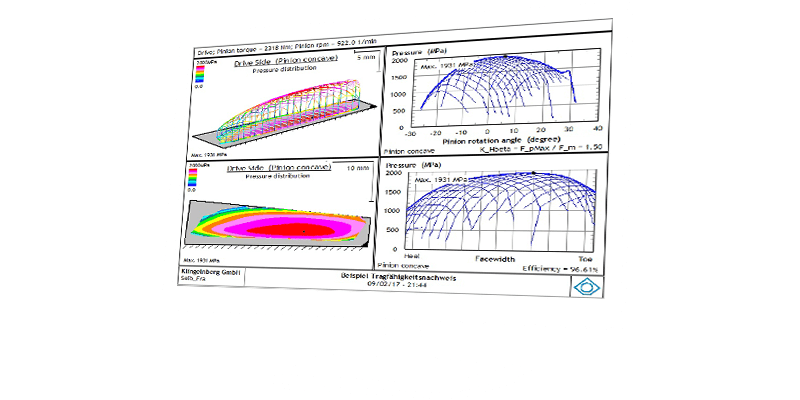

KIMoS (Klingelnberg Integrated Manufacturing of Spiral Bevel Gears) enables the design, optimization and computer-aided production of spiral bevel gears for various gearing systems. Based on a simulation of the production process and the intermating of tooth flanks generated in this way, the gear set running behavior can be examined in detail and optimized. All data records are organized in one or more databases containing the theoretical nominal data for topographical measurement of the tooth flanks, the theoretical machine setting values and tool data, as well as the optimized machine setting values.