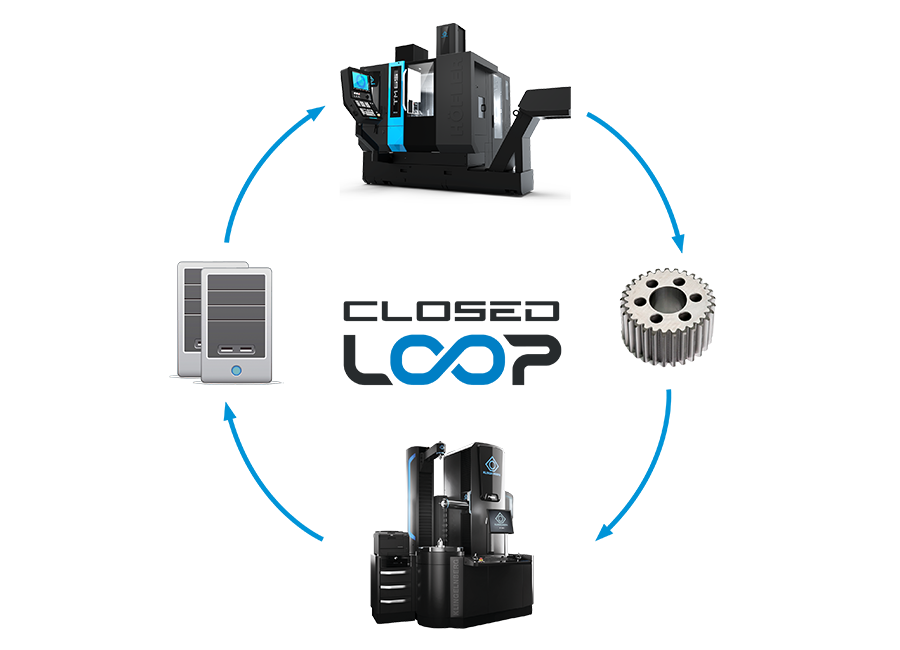

Highlight

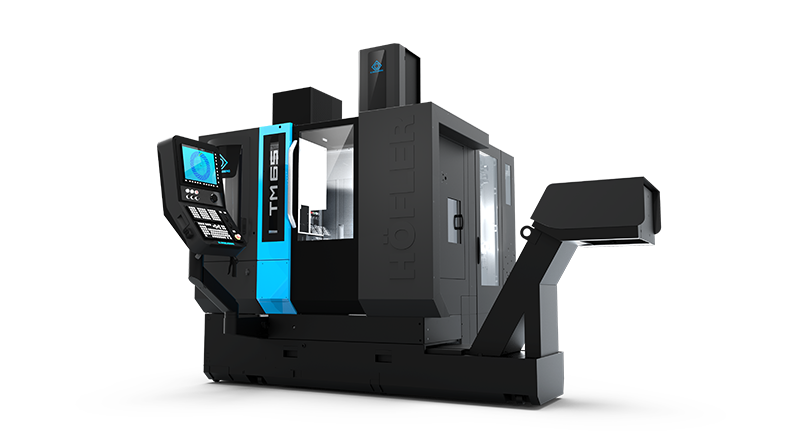

HÖFLER Complete Machining Center TM 65

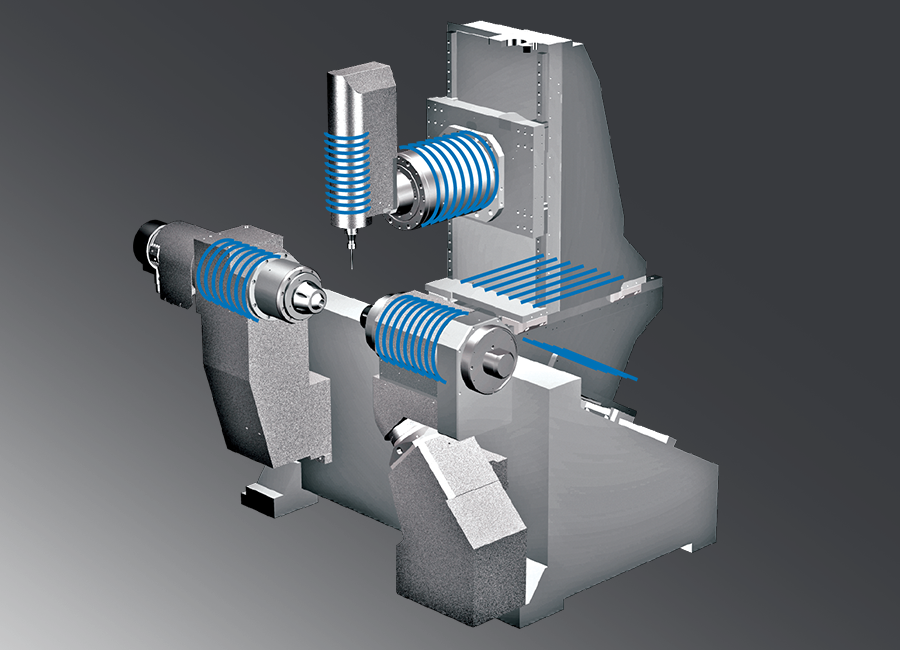

Complete Processing from the Rod

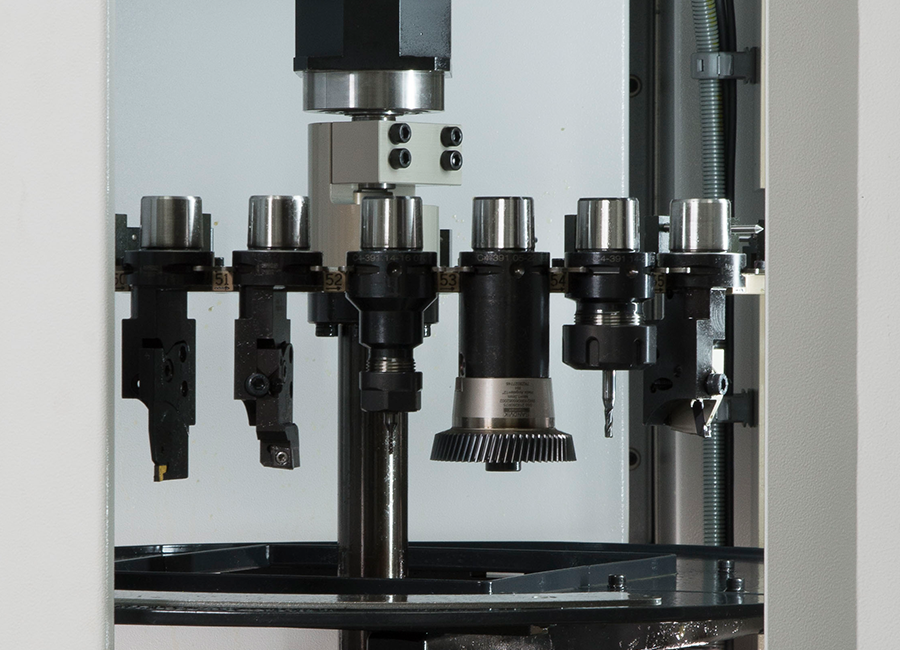

- Hainbuch main spindle / subspindle clamping system designed to process all surfaces of a component inside the machine

- Clamping system change-out takes just a few minutes

- Standard mounting arbors for grinding work

- Innovative kinematics for maximum processing with minimal space requirements

- Up to 90 tools allow for all types of machining