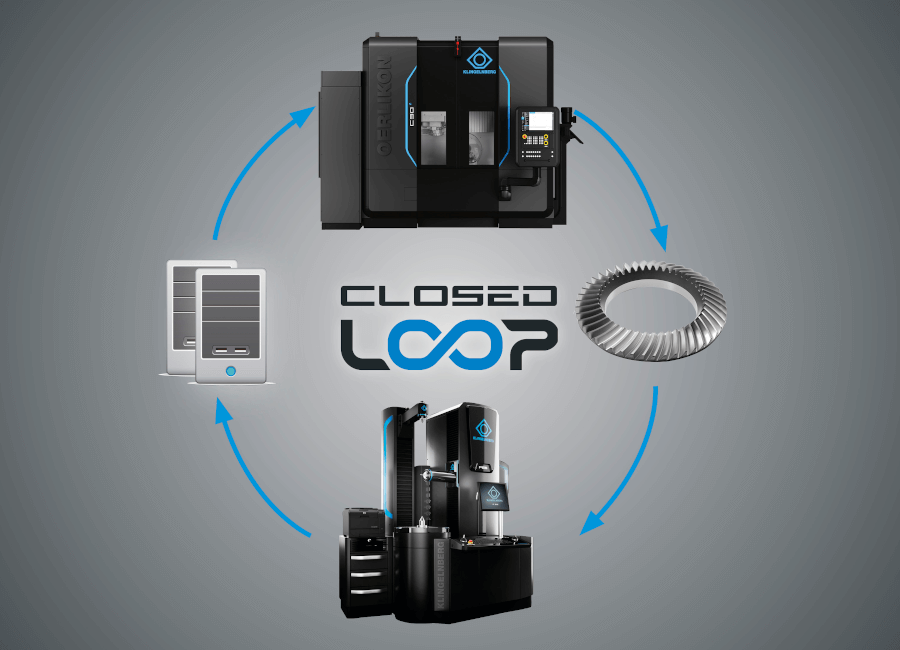

Highlight

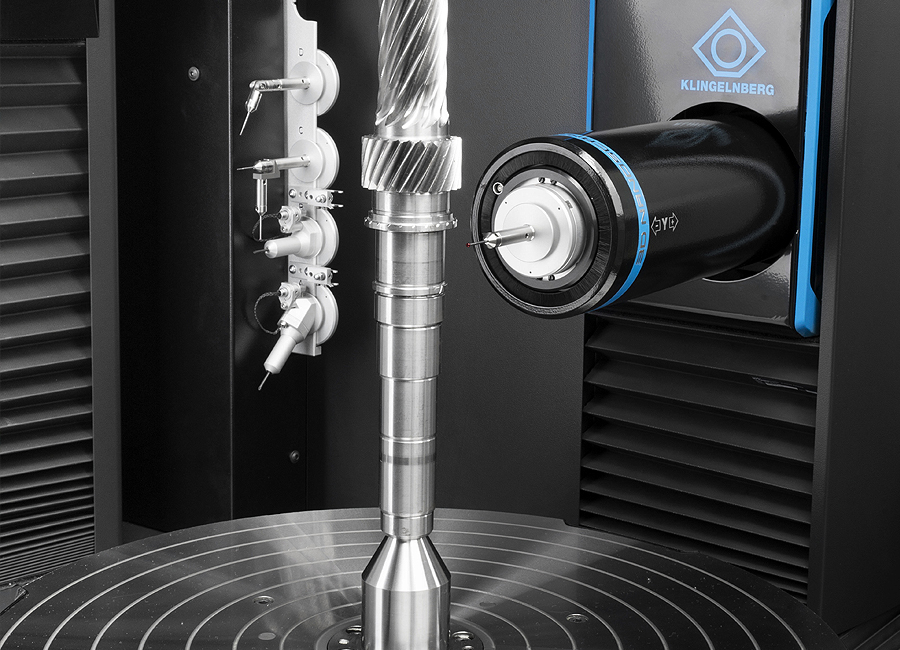

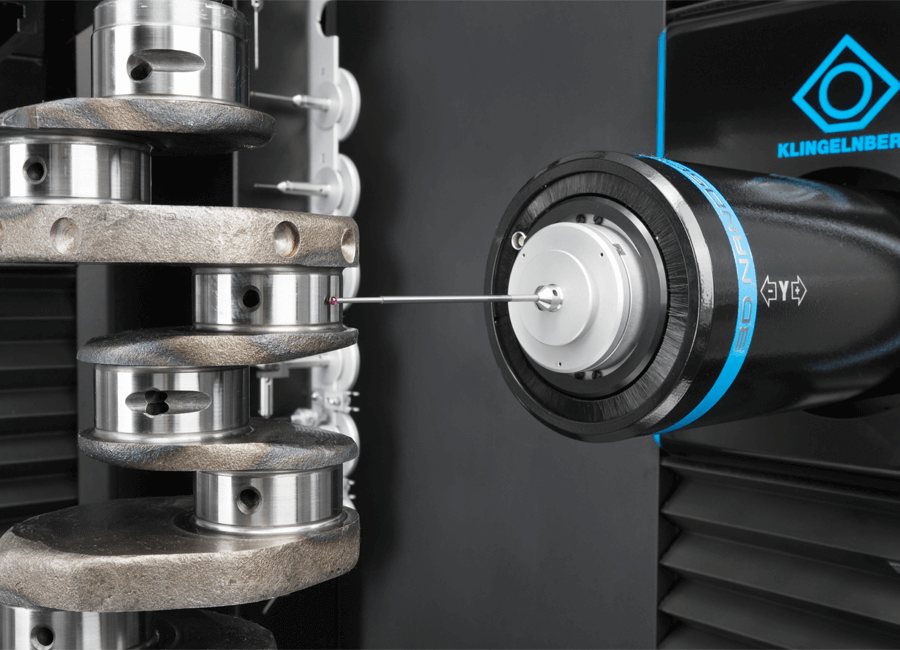

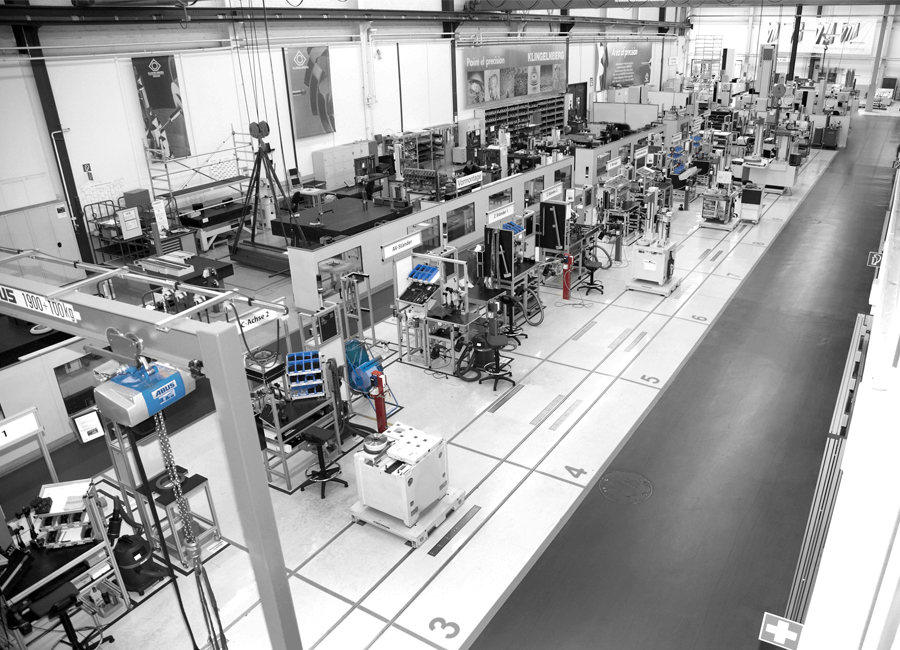

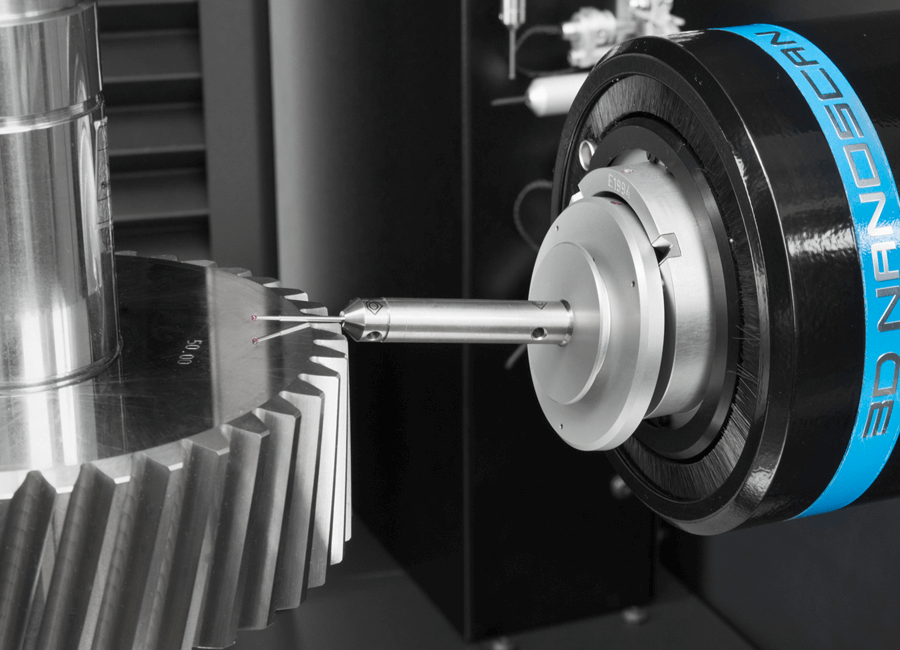

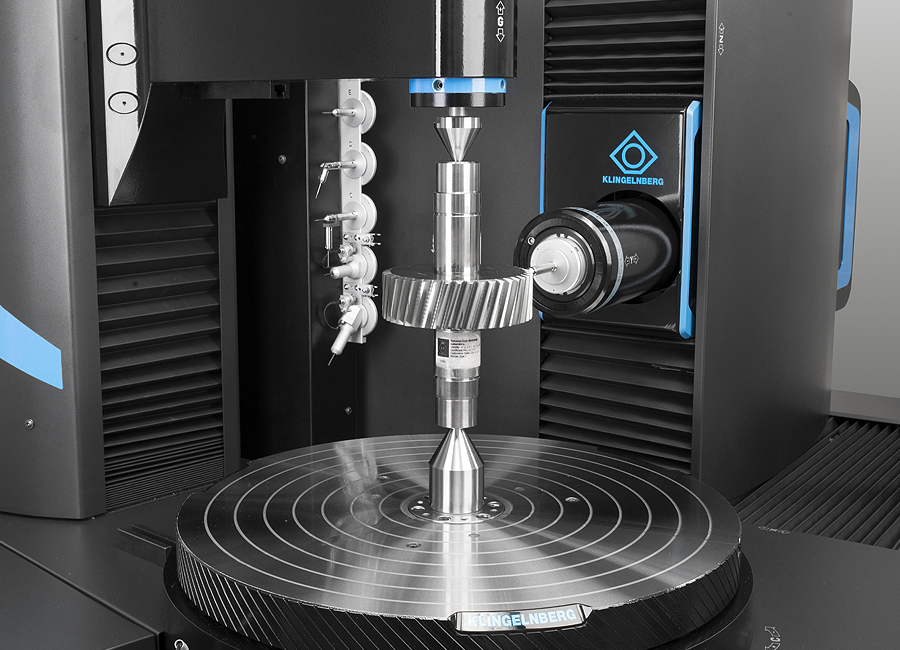

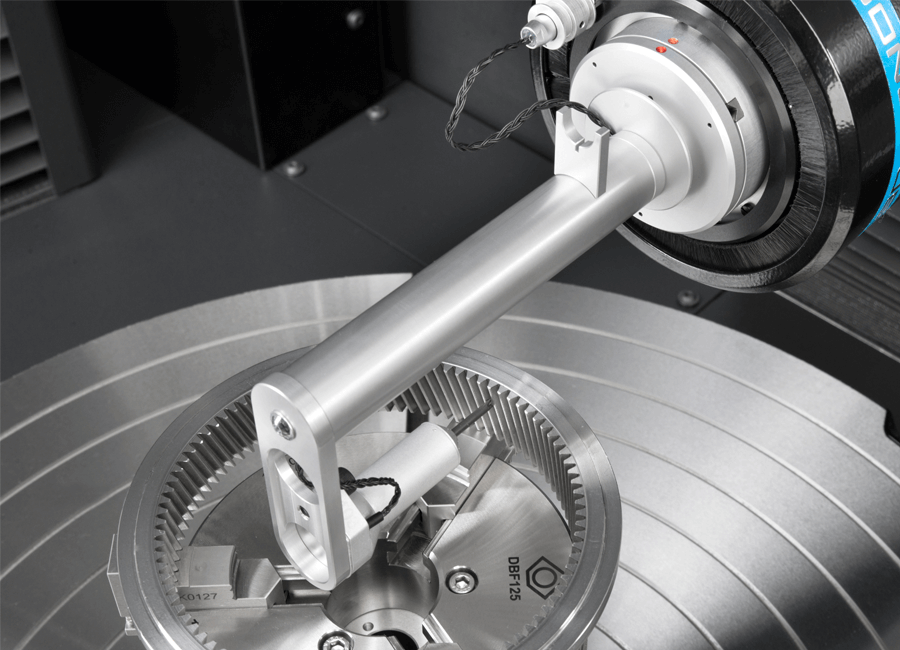

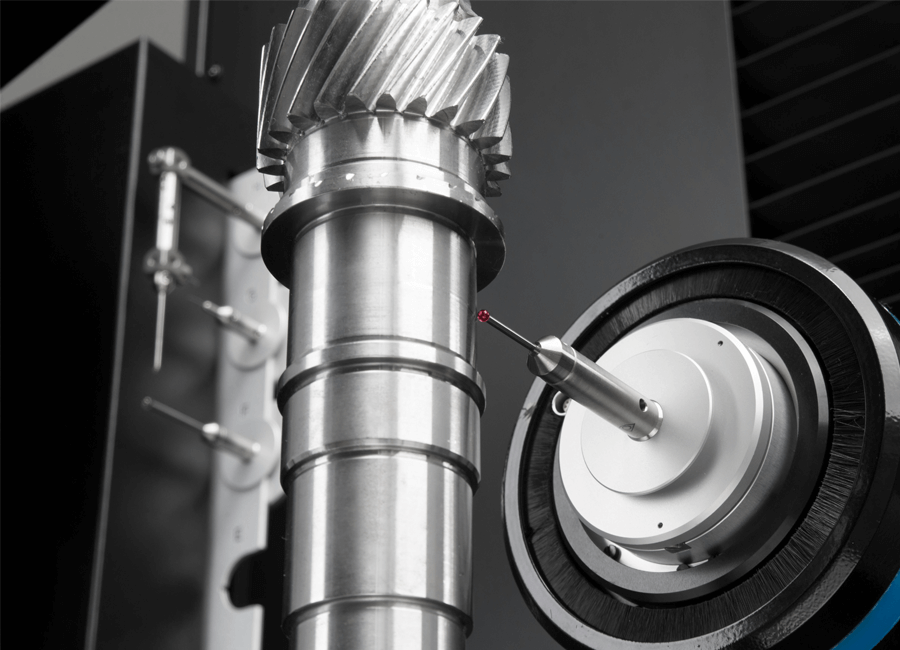

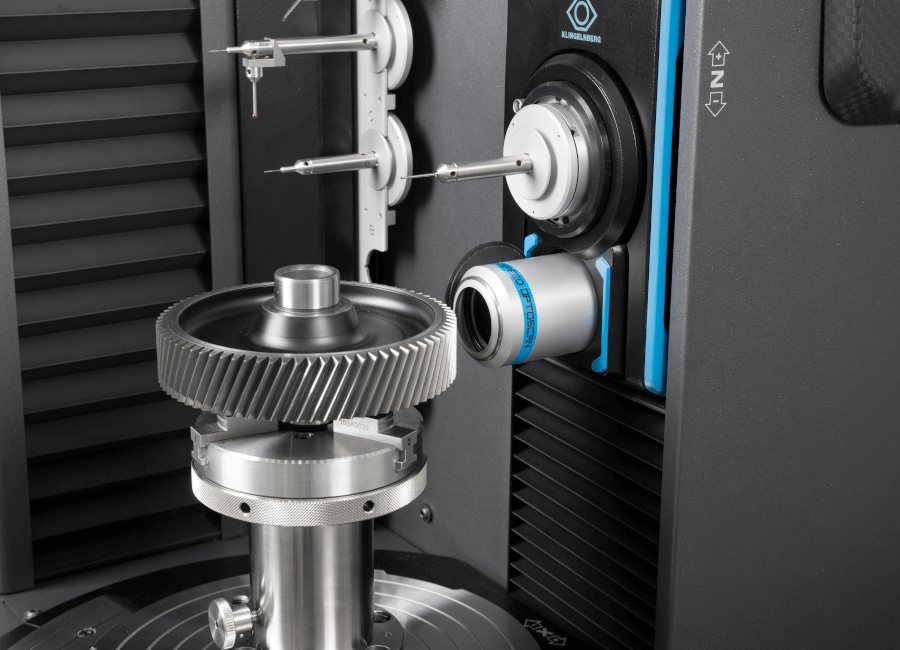

KLINGELNBERG Precision Measuring Center P 40

Fast and accurate measured value logging in connection with a high-precision workpiece rotary table

- Extremely smooth-running rotary table axis in form-measurement quality

- Load reserves for impacts during workpiece loading

- Rotary table drive via AC torque motor (direct drive)

- Uniform, constant rotary transmission even at extremely slow-motion

- Directly coupled angle measuring system with high absolute accuracy

- Table freely rotatable when drive is shut down