Highlight

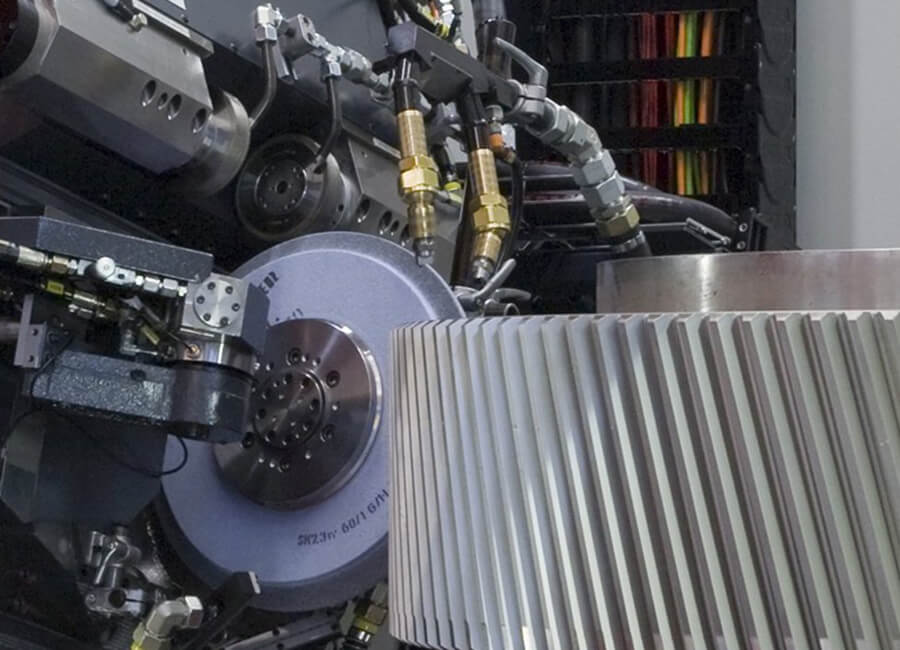

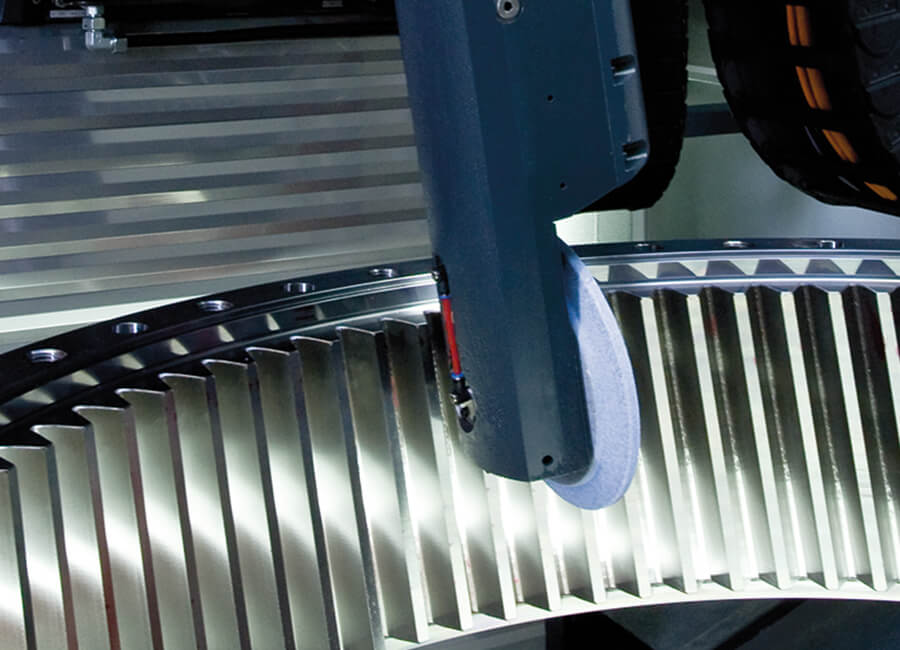

HÖFLER Cylindrical Gear Grinding Machine RAPID 3000

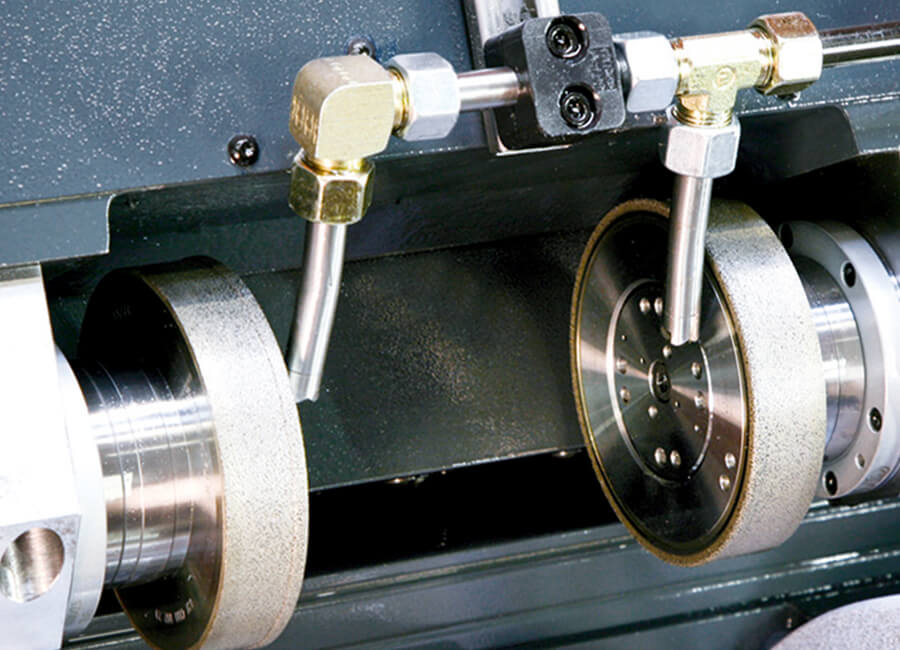

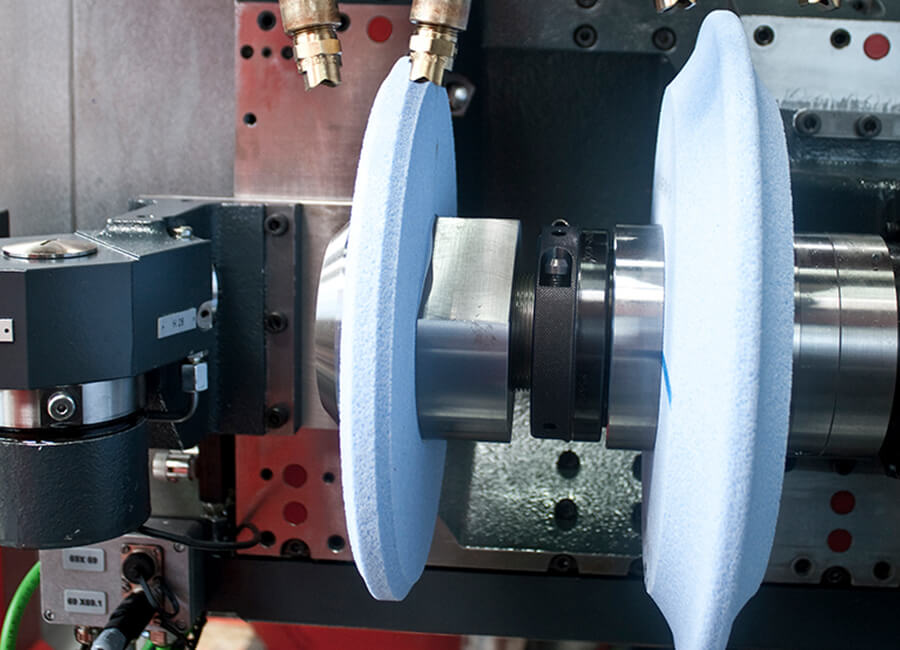

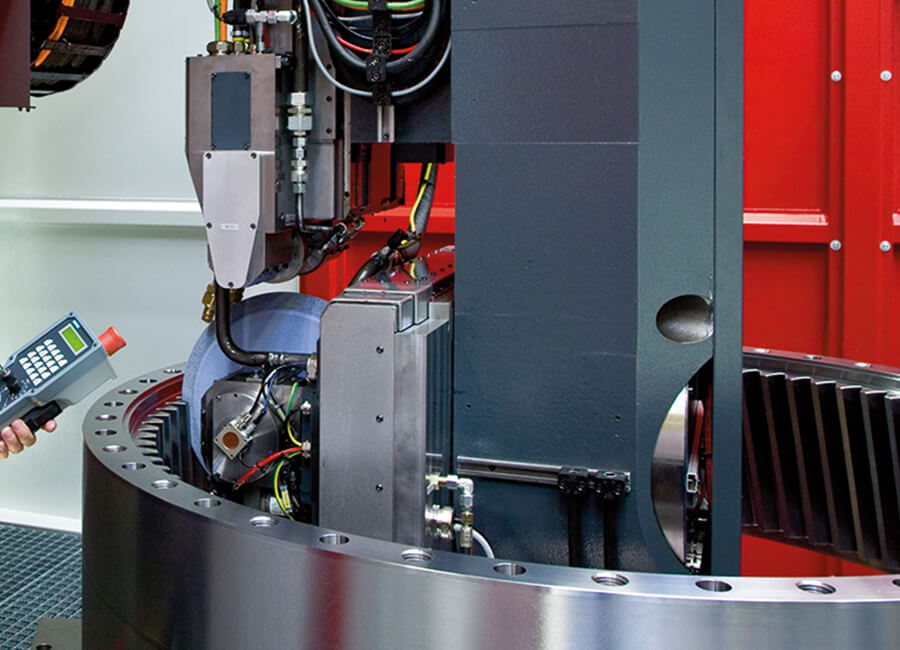

Highly flexible grinding head with torque motor swivel drive

- Genuine 5-axis machining possible

- Maximum rigidity and positioning precision as well as no wear even during the grinding process

- Grinding head position monitoring thanks to integrated measurement system

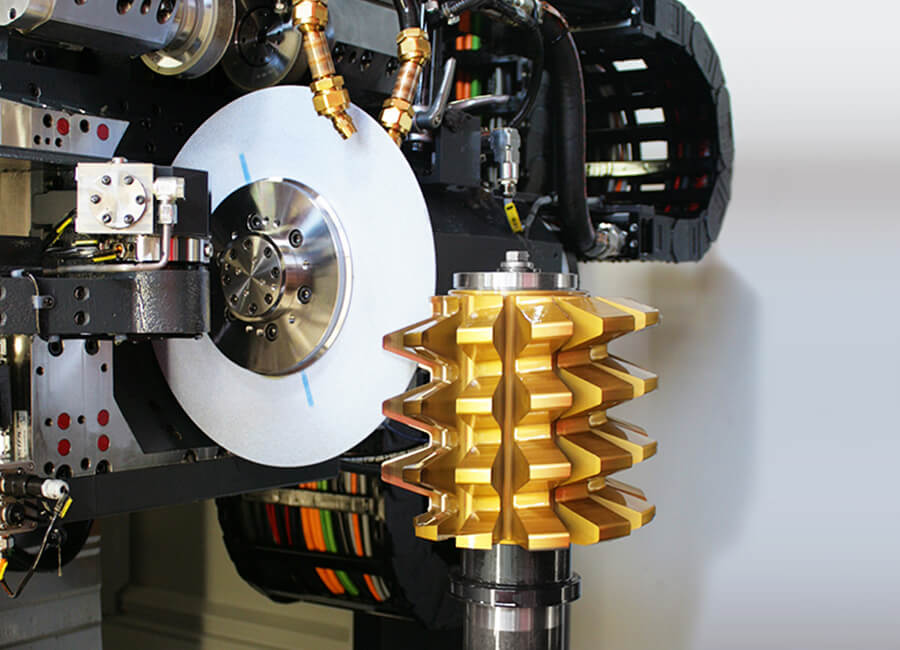

- Topological modifications depending on requirements in single-flank or double-flank grinding

- Integrated measuring device with 3D probe for checking the most difficult topologies on the grinding machine