In the eighth issue of its GEARS inline customer magazine, Klingelnberg presents the projects and developments it has advanced in recent months, with a special focus on trends and developments in renewable energy, particularly wind energy. An exclusive interview on this topic with Gary Gu, Executive Director the Asian gear box manufacturer NGC Transmission Equipment, reveals some fascinating responses.

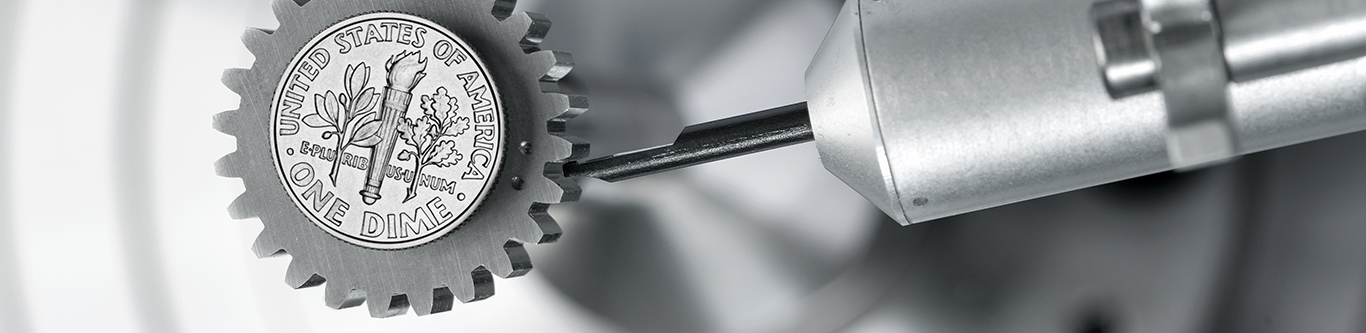

In addition to a range of solutions for wind energy, the current issue also includes impressive customer reports. Mexican automobile manufacturer Transmisiones y Equipos Mecánicos S.A. de C.V. (TREMEC) reports on its experience with the Höfler Cylindrical Gear Generating Grinding Machine Speed Viper. The customer received an entire production system consisting of design software, new operating software and an innovative machine. TANDLER GmbH & Co. KG, which specializes in gears and transmissions, demonstrates the advantages of retrofitting and explains when it’s worth it to overhaul a machine. Klingelnberg also introduces its latest machine development: With the Höfler Cylindrical Gear Roll Testing Machine R 300, Klingelnberg is introducing onto the market a machine that is designed for a compact, flexible, high-precision testing technology for 100-percent quality control of cylindrical gears.

Time for Wind Power: the Future of Energy Production

With the return of the United States, the Paris Climate Agreement is once again taking center stage. China is also pursuing an ambitious climate target, aiming to reach CO2 neutrality by 2060. Regenerative energy, particularly wind power, is playing an important role in the country’s growing energy demand. Gary Gu, Executive Director of the gearbox manufacturer NGC, and Prasad Kizhakel, Chief Sales Officer of the KLINGELNBERG Group, discuss opportunities, trends, and technologies.

Wind Turbine Generators – Concepts and Developments

The development of gearing technologies contributes to the technical progress of wind turbine generators (WTGs), offering a wide range of tooth flank design options that provide an important basis for high-performance transmissions. Dr. Hartmuth Müller, Head of Technology and Innovation, explains the history of wind turbine generators and highlights a range of concepts.

Volume Production and Precision Measuring Technology for Large Gears

Due to the worldwide expansion of wind energy production, the demand for large components is experiencing tremendous growth in the field of gears. A logical consequence of this is the targeted introduction of high-volume processes in large-gear manufacturing. Handling large gears for wind turbine transmissions poses very special challenges – and as a result, specific production-related solutions have been developed for efficient, automated volume production.

With the newly developed Precision Measuring Center P 152, designed for gears with a maximum outside diameter up to 1,520 mm and weighing up to 8,000 kg, Klingelnberg offers an innovative solution in measuring technology. Even for the “giants” among gears, with weights up to 30, 000 kg, there are high-precision measuring machines that can be used in a variety of applications.

Quality through Roll Testing

The Höfler Cylindrical Gear Roll Testing Machine R 300 is the latest machine development in the area of cylindrical gear technology. Designed for all five roll testing methods, this compact machine is the ideal high-precision testing technology solution for anyone who wants to combine inspection cycles and reduce disassembly costs while benefiting from a user-friendly design.

Classic Designs in the Aviation Industry, Manufactured Efficiently

Aviation technology occupies a special position in bevel gear manufacturing. This is due in part to the documentation required for the machining processes – nobody wants to have a gear problem at an altitude of 10, 000 m – and in part to the gear methods used. Designed specifically for volume production of fixed setting components, the Oerlikon G 35 special-purpose machine combines tried-and-tested aspects of a range of machine concepts.

Sights Set on Speed Viper – A Field Report

For over 20 years, the KLINGELNBERG Group has been represented in Latin America by KLINGELNBERG México, S.A. de C.V. In 1990, a full ten years before the local subsidiary was founded, the successful partnership between Klingelnberg and the Mexican automobile manufacturer, Transmisiones y Equipos Mecánicos S.A. de C.V (TREMEC), began with the purchase of the first PNC 30 measuring center on the Mexican market. In 2019, TREMEC added the innovative Höfler Generating Gear Grinding Machine Speed Viper to its machine fleet. Hector Simental, Operations Director at TREMEC, and Adrián Hernandez, Managing Director of Klingelnberg’s Mexican subsidiary, provided this report on the partnership.

When It’s Worth Retrofitting – a Practical Example

For many years, TANDLER Zahnrad- und Getriebefabrik GmbH & Co. KG, a specialist in transmission and gear manufacture, and the KLINGELNBERG Group have partnered together. Their latest joint project was the general overhaul of a KNC 60 bevel gear hobbing machine for workpieces up to 600 mm in diameter, which Tandler acquired in 1996. The objective was to bring the machine up to the state of the art at the lowest possible cost. Jan Greune, Head of Operations at Tandler, and Loïc de Vathaire, Service Manager, Bevel Gear Technology at Klingelnberg, are familiar with all the advantages of such a machine retrofit.

Klingelnberg Machine Gate

New IT technologies for old control units: Because cyber attacks are steadily on the rise, IT security plays an increasingly important role in the context of networked production systems. Klingelnberg Machine Gate provides a timely upgrade of security standards in older machines.

The Latest GEARS inline – Order Now!

You can order the latest issue from the Marketing department right now – either by phoning 02192 81-0 or by sending an email to marketing@klingelnberg.com with “GEARS inline” in the subject line. We hope you enjoy reading the new issue!