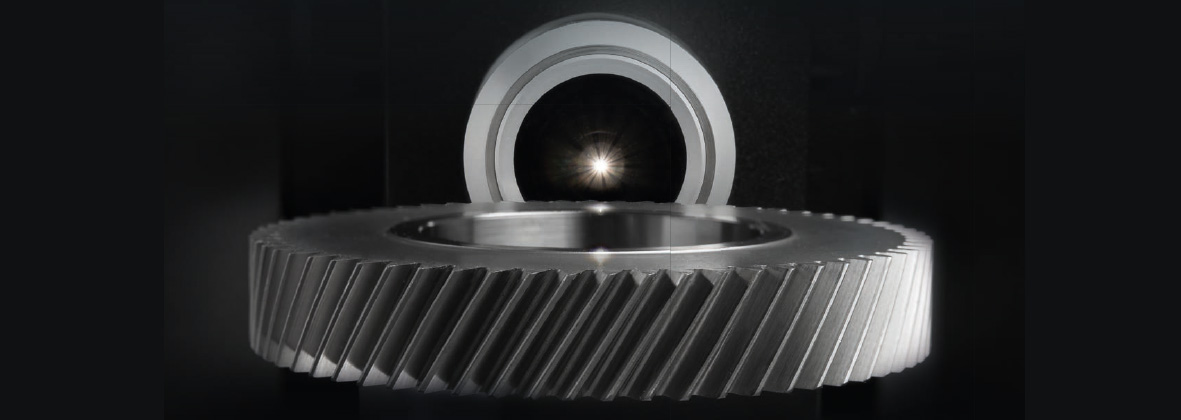

For quite some time, there has been a desire to implement optical measurement methods in gear inspection. Measurement times would be short, there would be no need to rely on a perfectly round ruby ball, and all probe rods would generally be eliminated, along with the complex calibration they entail. Enticing prospectives indeed, if only optical gear measuring technology worked as safe and precise as tactile metrology...

Klingelnberg Hybrid Metrology

TECHNOLOGY NEWSLETTER

TECHNOLOGY NEWSLETTER

AT A GLANCE:

TECHNOLOGY NEWSLETTER

- Klingelnberg Optical Metrology focuses systematically on shorter measurement times.

- Time savings of up to 80 percent can be achieved with optical pitch measurement.

- With hybrid gear measurement, total measurement time in one sequence can be reduced by up to 40 percent without compromising measuring accuracy.

Klingelnberg Hybrid Metrology

TECHNOLOGY NEWSLETTER

Whereas the initial development stages of optical metrology were focused on applications used primarily in the lab, the solution now available is systematically oriented toward series application of cylindrical gear measurement. The primary advantage here is greater efficiency through a reduction in measurement times of up to 40 percent.

When developing optical measuring technology, Klingelnberg focused on reducing measurement times

TECHNOLOGY NEWSLETTER

KLINGELNBERG HYBRID METROLOGY

In serial measurement of a cylindrical gear, the profile and lead are typically measured on three or four teeth, and pitch measurement is performed on all teeth. This tactile pitch measurement necessarily involves inserting the stylus into each gap. With optical measurement, by contrast, nothing is inserted into the tooth gap. Accordingly, pitch measurement offers the greatest potential for reducing the measurement time. Through optical pitch measurement using one continuous, uninterrupted rotation of the component, the measure ment time advantage increases with large numbers of teeth to up to 80 percent. This optical pitch measurement is combined with the tactile measurement of profile and lead. Overall, the total measurement time decreases by up to 40 percent. Thus in cases where there is a high utilization rate of the measuring machine, the costs for the optical metrology option are quickly recovered. The technology therefore makes a significant contribution to reducing quality costs in the first step.

But decreased measurement time is not the only key factor

TECHNOLOGY NEWSLETTER

KLINGELNBERG HYBRID METROLOGY

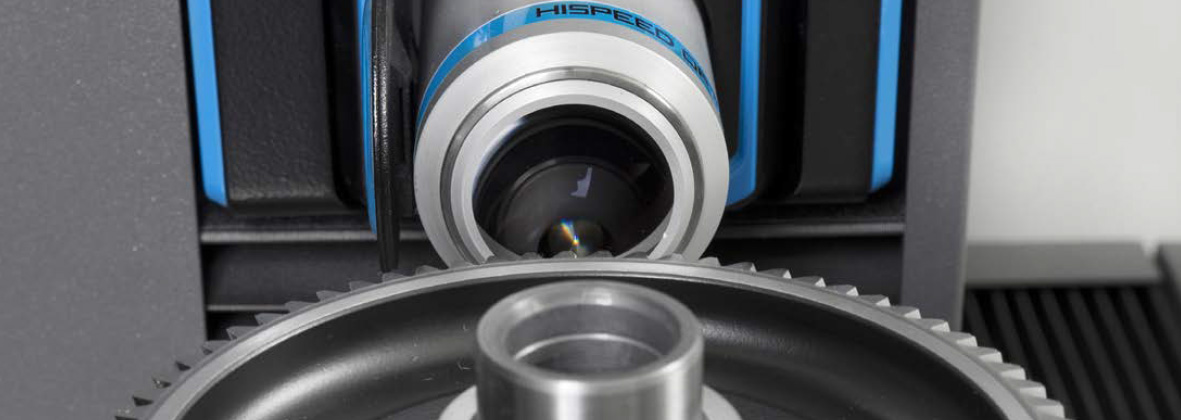

Just as important is a high achievable accuracy of the measuring results, even in the case of extremely complex gears with ground surfaces and steep profile angles. This is the result of intensive optimization of the sensor technology, the analysis algorithms, and the measurement strategy. The only difference in operation is that optical pitch measurement must be selected in the same cylindrical gear measurement software customers are already familiar with. The measuring run is automatically modifi ed accordingly, and the pitch measurement is performed with the optical sensor. The changeover between the tactile 3D NANOSCAN probing system and the optical HISPEED OPTOSCAN sensor takes place automatically within approximately 1.5 seconds in conjunction with the entire measuring run. In terms of achievable measurement time advantage, one thing is true: The more teeth there are, the bigger the advantage.

Comparison of the measuring times for pitch measurement on different gear

TECHNOLOGY NEWSLETTER

KLINGELNBERG HYBRID METROLOGY

| Number of teeth [z] | Standard module [m] | Measuring time tactile* [s] | Measuring time optical* [s] | Measuring time savings [%] |

|---|---|---|---|---|

| 63 | 1,52 | 114 | 27,5 | 75.9 |

| 29 | 2,197 | 71 | 20 | 71.8 |

| 21 | 2,2 | 47 | 11.8 | 74.9 |

| 75 | 1.9189 | 133 | 37.3 | 72.0 |

| 36 | 4,0 | 74 | 28.2 | 61.8 |

| 95 | 1.4 | 164 | 45 | 72.6 |

| 67 | 1.529 | 126 | 37 | 70.6 |