The KLINGELNBERG Group will be presenting its products at the "IMTEX" exhibition in Bangalore, India, from 19 to 25 January 2023. One of the largest exhibitions for the metal-cutting industry in India, the week-long trade show presents the complete spectrum of products and technologies in the machining industry. Klingelnberg (represented by its Indian subsidiary, KLINGELNBERG India Pvt. Ltd.) will also be on hand, showcasing its extensive line of products and services at Booth B106 in Hall 4. Alongside the tried-and-tested applications, Klingelnberg will also be exhibiting new solutions.

Visitors will get hands-on experience with a range of applications demonstrated on the P 40 Precision Measuring Centers. Klingelnberg Precision Measuring Centers systematically follow the approach of processing as many measurement tasks as possible on one machine. They execute the entire process in a single automated sequence directly on the shop floor. Particularly when producing large series of axially symmetrical drive elements with their many GD&T features, it is important to monitor the process in real time and as close as possible to the production environment. The P-series has proven itself particularly in these types of shop-floor applications. Klingelnberg Precision Measuring Centers themselves are used as a reference around the world, not just by countless customers, but also by renowned metrology institutes.

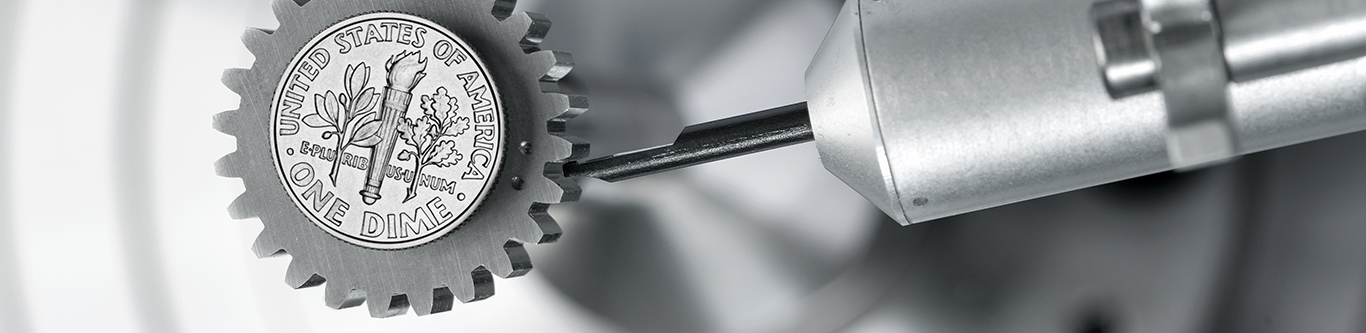

ROUGHNESS MEASUREMENT

Product Highlights

CUTTING-EDGE TECHNOLOGY FOR MAXIMUM PRECISION

- Fully automatic roughness measurement now possible from module 0.9

- High-precision sensing and evaluation of superfine structures on surface-ground gearings

All precision measuring centers in the P-series can be equipped with a high-precision roughness measurement device. This roughness measurement can be integrated fully automatically into both the gearing measurement and the coordinate measurement, allowing all measurements to be conducted in one clamping.

- Fully automatic roughness measurement of gearings from as small as module 0.9 mm, as well as shafts and plane surfaces

- Evaluation of roughness parameters according to DIN EN ISO 4287 (Ra, Rz, Rt, Rmax)

- Evaluation of contact ratio parameters according to DIN EN ISO 13565-2 (Rk, Rpk, Rvk, MR1, MR2)

- Skid sensing system for effective separation of the usable signal from ambient influences

- Integrated motorized swivel device for automatic alignment of the diamond needle with a diamond tip radius of 2 µm or 5 µm

- Optimal scanning conditions with measuring runs similar to gear measurement

- Comprehensive collision protection

- Optimized design to protect the diamond needle

- Extremely high resolution of 7 nm

- Robust, reproducible measuring results even on extremely smooth (e.g., surface-ground) surfaces

- Easy handling through integration into the normal measuring process

- Precise measurement, even in the shop-floor environment

- Fully automatic procedure for probe change (option)