Promoting young talent has always been an extremely important focus for machine manufacturer Klingelnberg. Training its own qualified personnel is one of the most important things the company does to counter the ever-increasing shortage of skilled workers. This was the impetus behind a project developed by Klingelnberg’s current vocational trainees to give prospective vocational trainees insight into their professional fields through a series of short videos.

In addition to vocational training in the industrial, technical, and commercial areas, Klingelnberg currently also offers dual-track studies and cooperative engineer training (KIA in German). In partnership with the Hückeswagen vocational college, candidates have the opportunity to combine training paths, for example, by obtaining a full commercial or technical training degree and a full Abitur diploma from a German secondary school, qualifying them for university admission. The company also offers internships for secondary-school and university students.

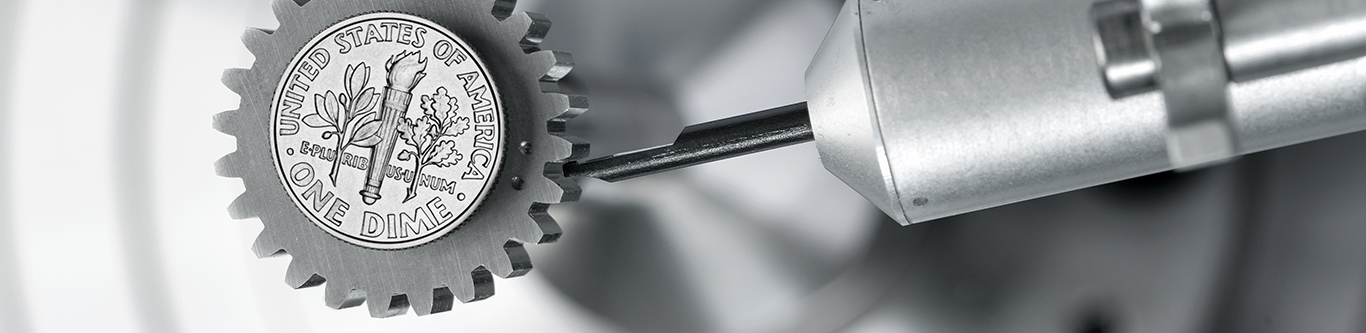

“As a leader in the gear industry, we are preparing to face the challenges of the future,” explains Dennis Weiche, Head of Human Resources at Klingelnberg. “In the area of training, we are doing this by targeting specific company requirements. As a result, our vocational training programs take into account all of the professional profiles that are relevant for us, now and in the future.

Particularly in view of demographic trends, every company today is challenged to find new ways and adopt alternative approaches for attracting and motivating highly skilled young people for the company and gaining their loyalty over the long-term,” notes Weiche.

Klingelnberg vocational trainees introduce themselves in a series of short videos

Anyone interested in learning more about the individual industrial trades learned through an apprenticeship at Klingelnberg can go to the KLINGELNBERG YouTube channel for an initial overview. A part of a project they developed, the vocational trainees at Klingelnberg have come up with a great way to introduce the skilled trades they are learning to future vocational trainees. In short videos lasting approximately 120 seconds, they present their fields of activity, explain what they really love about the profession, and tell the viewers what vocational training is really all about. The end product is available for everyone to see on the Klingelnberg YouTube channel.

Apply now for the 2022 training year

All training positions within the KLINGELNBERG Group can be viewed on the website at career/training. Our Human Resources department is welcoming applications for the coming year by e-mail at ausbildung(at)klingelnberg.com.