INNOVATION IN COMPONENT MEASUREMENT

Product Highlights

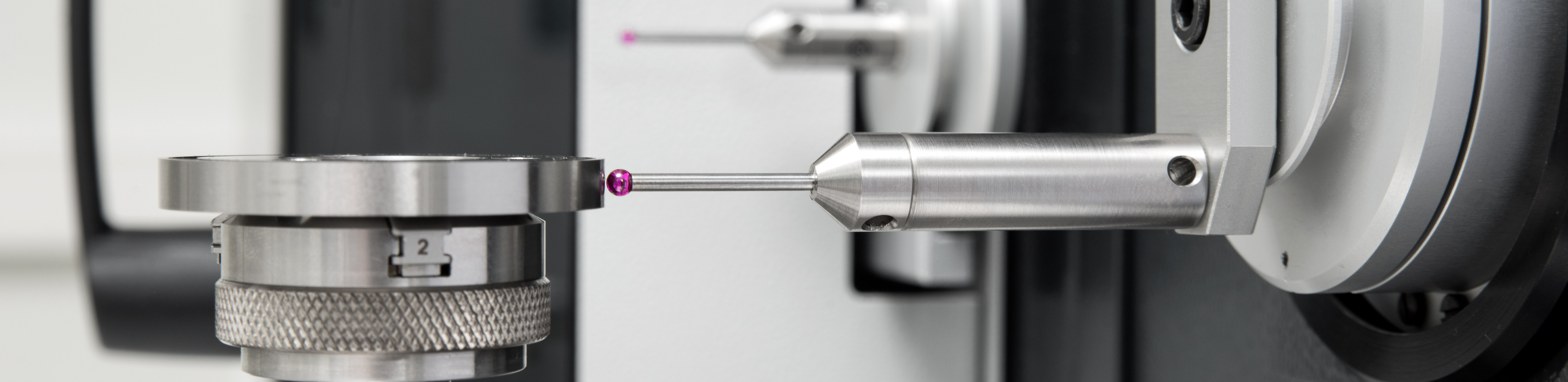

INNOVATIVE QUALITY MANAGEMENT OF AXIALLY SYMMETRICAL COMPONENTS

Whether turning blanks, ground workpieces, circular blades, spacers for circular blades, or ball bearings – the new P 16 G precision measuring center is purpose-designed – not to measure gear teeth, but rather specifically for use in manufacturing round components. The P 16 G is the only machine in the

P series to be equipped with software for dimension, form, and position measurement as standard. The software records diameter and cylindrical form/conicity, measures axial runout, evenness, and angularity, and delivers a wealth of information for quality management as required. Hence with this precision measuring center, there’s no need for gauges.

Stringent precision requirements in series production and increasing component complexity both call for the best available measuring technology. The trend toward smaller batch sizes and growing variant diversity is increasingly shifting the focus towards the flexibility of measuring instruments. Today the P 16 G precision measuring center is already able to handle most measurement tasks in a wide range of sectors and industries: Automotive, machine blades, tools, roller bearings, and measuring instruments.

Klingelnberg universal precision measuring centers are currently in use along the entire production chain for axially symmetrical components. The P 16 G is optimally designed for the production process and for direct shop floor use. After each manufacturing step, every feature can be immediately displayed graphically or in table format, analyzed, and statistically evaluated, enabling efficient process control and reliable management of production processes. The basic software also includes storage of statistical data for further evaluation, e.g. warning limit specifications. And the P 16 G is incredibly easy to operate.