Highlight

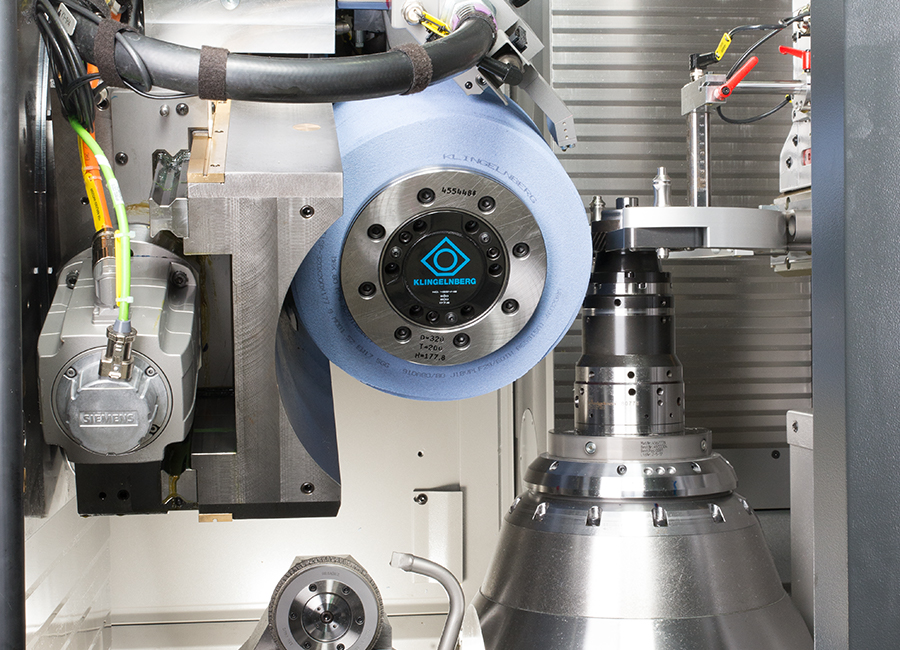

HÖFLER Cylindrical Gear Grinding Machine Speed Viper 300

Innovative Machine Design for Maximum Productivity

- Cutting speeds up to 100 m/s

- Rugged machine design, made of vibration-damping cast polymer

- Optimal automation capability for minimal auxiliary times

- Use of long-life tools

- Compact design with minimal travel paths in the process

- Large dressing roll diameters for a long service life

- High-performance, aerodynamic nozzle for efficient coolant supply