Highlight

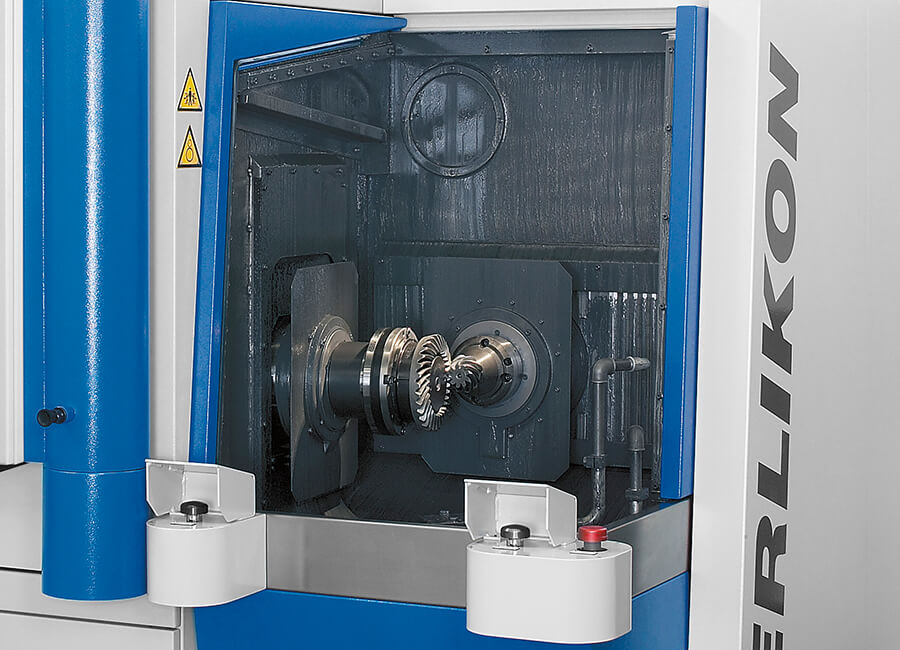

Oerlikon Bevel Gear Lapping Machine L 60

User-friendly machine design

- All operational tasks, such as loading, unloading, and retooling, can be performed from the front

- Wide-opening working chamber provides easy access for retooling and manual loading

- Intuitive user software prevents improper operation

- All necessary settings, such as machine setup, lapping process optimization, lapping and use as a roll tester, can be made using sturdy “one-touch keys”

- Optional foot switch to clamp or release workpieces