Highlight

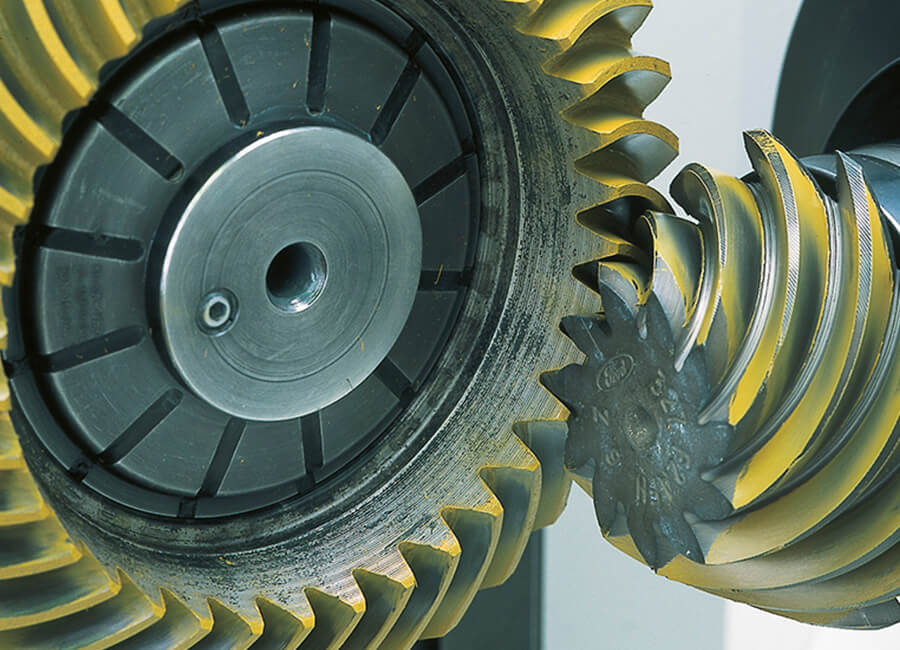

Oerlikon Bevel Gear Testing Machine T 60

Operator-friendly, easy-to-service machine design

- All operational tasks, such as loading, unloading, and retooling, can be performed from the front

- Wide-opening working chamber provides easy access for retooling and manual loading

- Intuitive user software prevents improper operation

- Optional foot switch to clamp or release workpieces

- Efficient maintenance thanks to easy accessibility

- No hydraulics

- Easy-to-read pneumatics layout on a central panel