Highlight

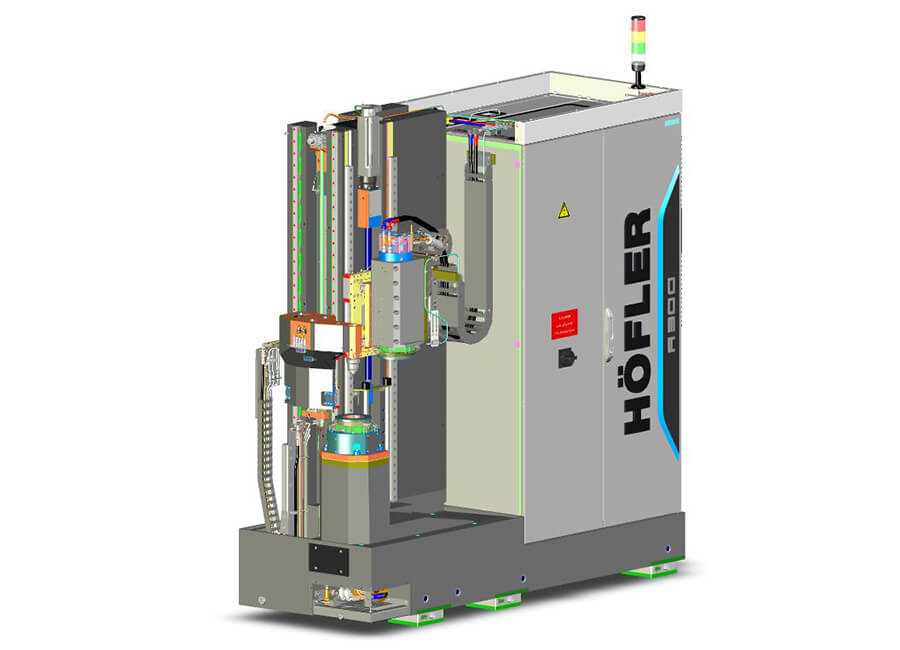

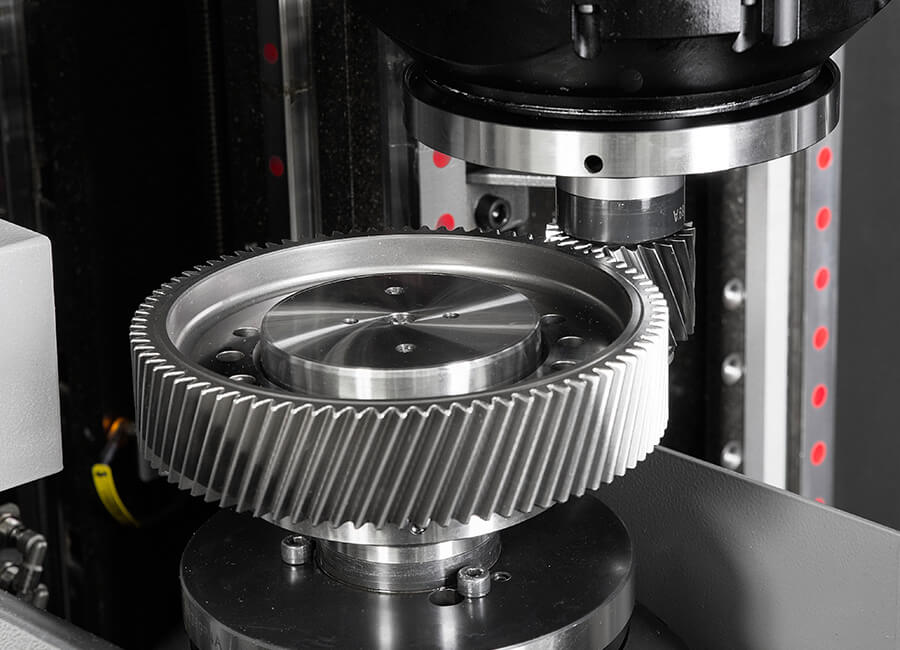

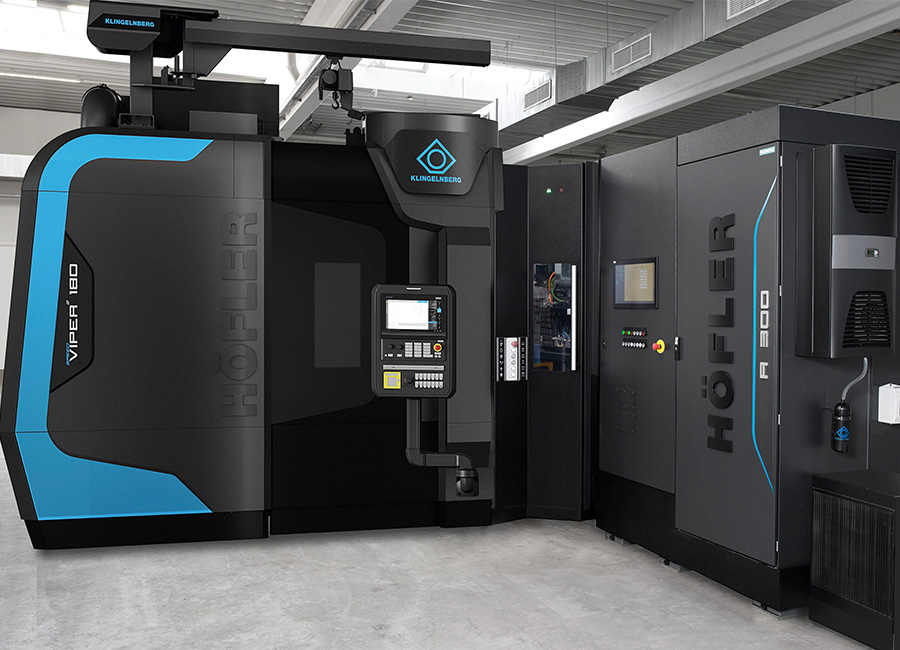

HÖFLER Cylindrical Gear Roll Testing Machine R 300

Modular Machine Design

- Ideal for testing the component spectrum of the Speed Viper series

- Same base machine for gear and shaft components

- Counter support for shaft testing (optional)

- Test slide with fixed installation height or optional manual or automatic height adjustment