Agriculture

Industry Solutions

The trend in agriculture: The drives of machines and commercial vehicles must be capable of transmitting increasingly high power within a limited space. Reproducible quality in series manufacture with the shortest possible production times are the key requirements in this industry.

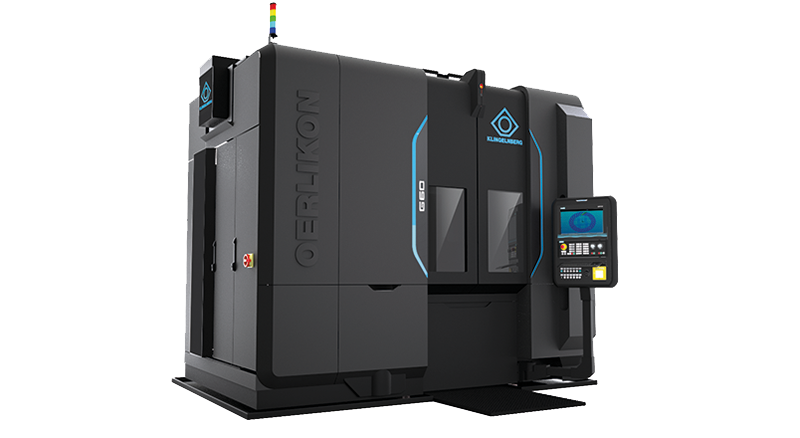

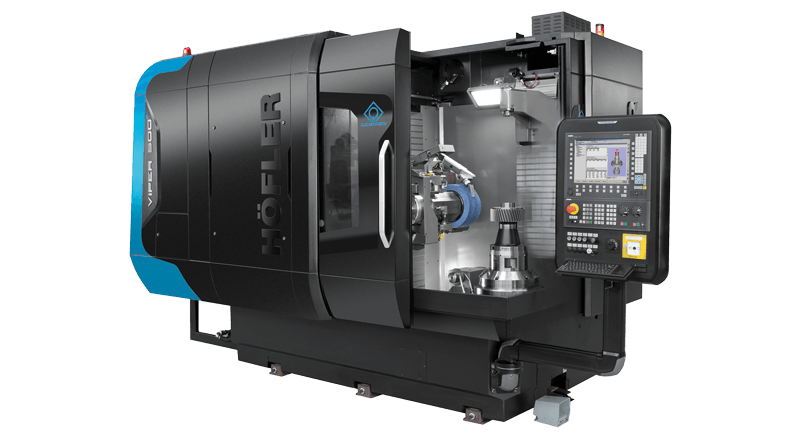

The hay makers and harvesters perform their task using straight bevel gears. Because the loads in these machines are comparatively small, a cost-effective manufacturing solution is crucial for the market success of straight bevel gears. It’s a different story as far as tractors are concerned: Spiral bevel gears are installed in the rear axles in this case – and the bevel gear set of a tractor’s rear-axle differential must transmit up to 400 kW. In tractors, cylindrical and planetary gears are also used in manual transmissions and counter shaft transmissions as well as planetary gear drives for transmitting power to the enormous drive wheels. These cylindrical and planetary gears must be efficient, quiet-running, and low-maintenance. With solutions from Klingelnberg, the entire portfolio can be produced on bevel-gear and cylindrical-gear machines.