Highlight

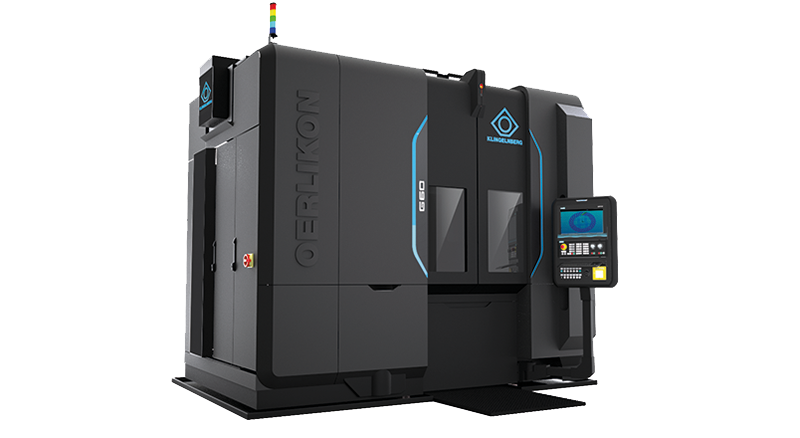

Oerlikon Bevel Gear Grinding Machine G 60

Vertical machine concept for reliable process sequences

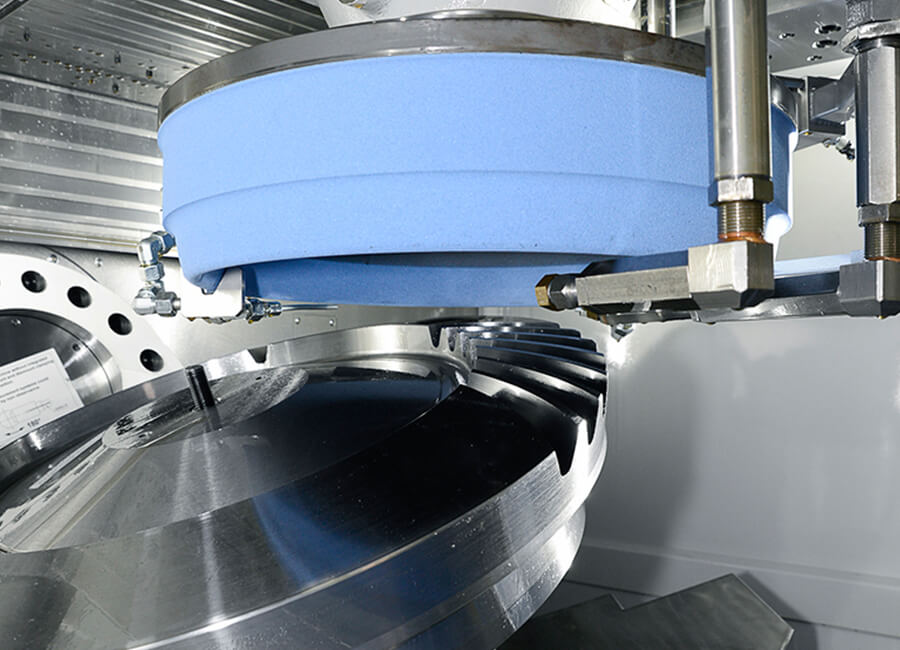

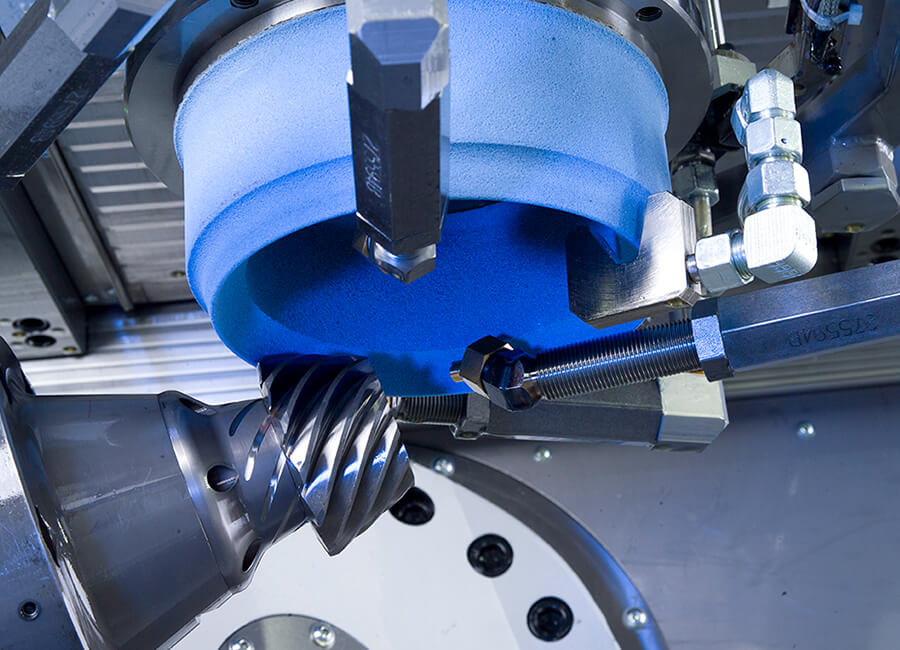

- Vertical grinding spindle for optimal swarf disposal

- Excellent visual process monitoring during the process positioning, thanks to optimal machining position of vertical grinding spindle

- Workpiece and workholding change in vertical direction are “gravity-assisted”

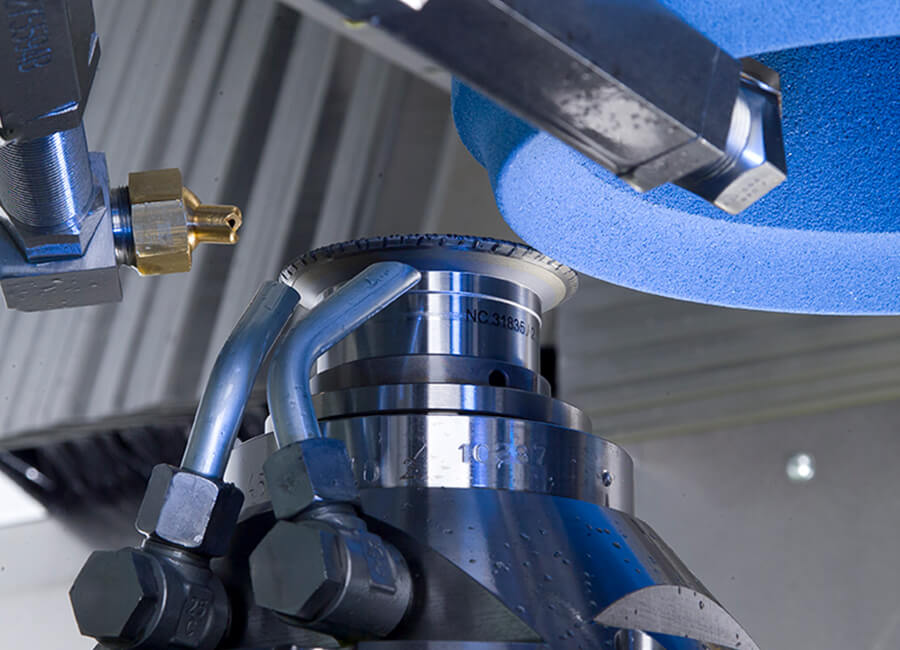

- Flexible oil nozzle system suitable for high pressure and quick change