Highlight

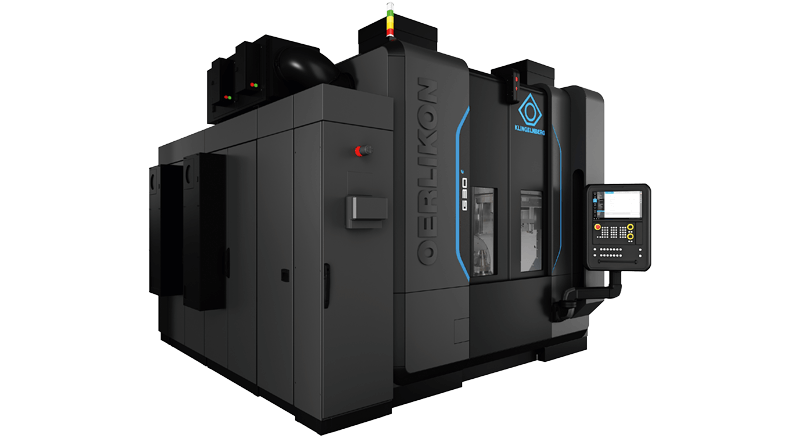

Oerlikon Bevel Gear Grinding Machine G 30

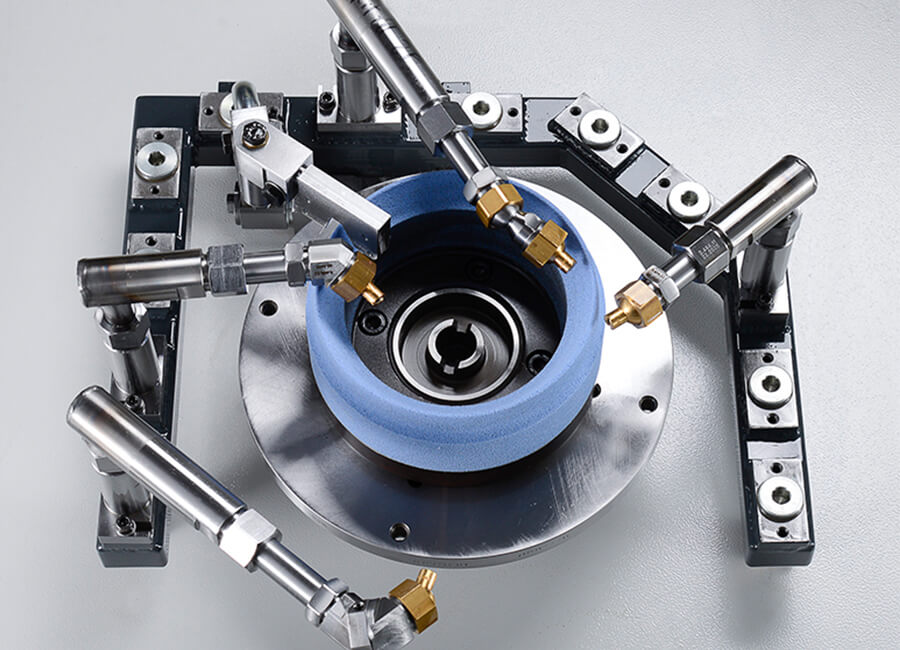

Vertical machine concept for secure process sequences

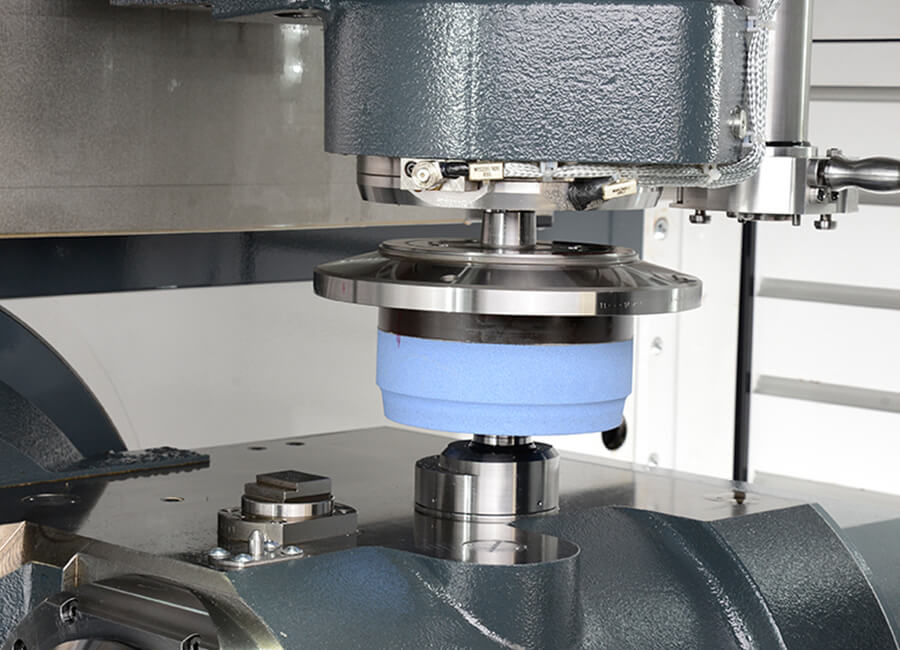

- Vertical grinding spindle for optimal swarf removal

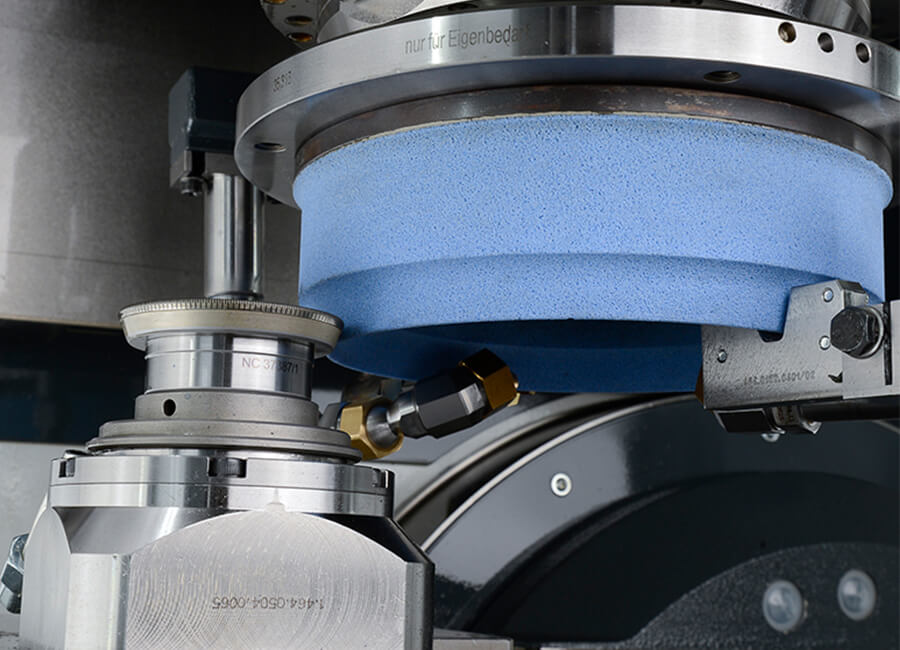

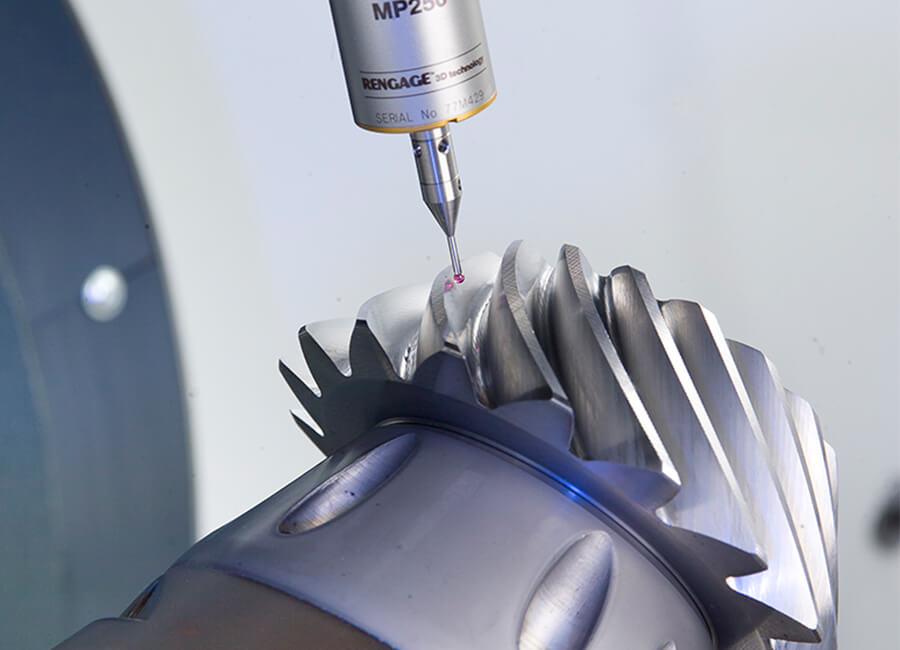

- Excellent visual process monitoring during process set-up, thanks to optimal machining position of vertical grinding spindle

- Component and clamping device “gravity assisted” in vertical direction

- Smooth surfaces and minimal interference contours in the working chamber combined with efficient interior cleaning to eliminate grinding swarf deposits (optional)